Table of Contents:

- Introduction to the Allison 10L1000 Transmission

- Allison 10L1000 Product Resources

- Popular Transmission Information Resources

- In this Drivetrain 101, we will be addressing

- Problem #1 - The Torque Converter Lockup Mechanism

- Problem #2 - The Stator

- Problem #3 - Functional Issues Caused by Added Power

- Problem #4 - The “E” Clutch Hub

- Problem #5 - The OEM Oil Pan

- Problem #6 - The High Pressure Oil Pump

- Problem #7 - The Valve Body

- Problem #8 - The Electronics

- Frequently Asked Questions about the 10 Speed Allison 10L1000 Transmission

- Conclusion to the Allison 10L1000 Transmission

Introduction to the Allison 10L1000 Transmission:

As the inventors of the famous Project Carbon 10L1000 High Pressure Valve Body Upgrade Kit, we at Next Gen Drivetrain are proud to be at the forefront of the 10L1000 market. If you own a late model GMC or Chevrolet 2500 or above with the L5P DuraMax diesel, you likely know Next Gen Drivetrain as the best place for uparmored 10L1000 transmissions and parts, designing unique parts and building them for a diverse spectrum of applications. All too often, we are approached with question after question about this highly complicated transmission; ranging from what fails to why and how. Fortunately, we've fulfilled this demand with an installment in our popular Drivetrain 101 series.

To get straight to the point, the Allison 10 Speed 10L1000 was released for the 2020 model year in General Motors heavy duty Silverado and Sierra trucks and is currently in use today. This transmission is easily the most robust, well engineered and dynamic transmission to be paired behind the DuraMax series trucks to date.

It is the successor to the 6 Speed Allison 1000 Transmission, whose tenure began in 2001 with the LB7 DuraMax and ended in 2019 under the L5P years. You can learn more about the 2001 through 2019 Allison 1000 Transmission by reading our Drivetrain 101 on the 5 & 6 Speed Allison 1000/2000 Series Transmission.

In fact, it has the highest relative torque capacity of any transmission released in this class to date, far exceeding competitors such as the AS69RC or 6R140. One thing that should be noted about the Allison 10L1000 is that this transmission is a fraternal twin of the Ford TorqShift 10 Speed 10R140. In fact, this transmissions internal components are largely interchangeable with those of the Ford, the parent engineer of this product.

Though this is generally a “good” transmission, it does have a fair number of easy to address problems that simply require some data analysis and technical understanding. In fact, we compiled all of this data into our version of the 10L1000, seen below.

That stated, and without further ado, we will address the most prolific problems, solutions and upgrades available for the new Allison 10 Speed 10L1000 Transmissions.

Allison 10L1000 Product Resources:

- 10L1000 Transmissions

- 10L1000 Torque Converters

- 10L1000 Rebuild Kits

- 10L1000 Valve Bodies

- 10L1000 Parts

Popular Transmission Information Resources:

- Top 5 Benefits of an Upgraded or Built Transmission

- Calculating Torque Multiplication Factor, Why is it So Important?

- Top 5 Ways to Extend the Life of a Factory Transmission

In this Drivetrain 101, we will be addressing:

- The most popular failures we witness on the Allison 10L1000 transmission

- Its capabilities (or lack there of) in reference to TCM tuning and shift/lockup protocol modification

- The strengths (believe it or not, there are a few!) of this transmission

- Footnotes for Chevrolet AND GMC owners

And much, much more!

Problem #1 - The Torque Converter Lockup Mechanism

If there is one Achilles’ Heel to this transmission, it is the dismally inferior OEM torque converter. There is a lot of good AND a lot of bad, so we have divided this into multiple sections. The problem here is ironically not design, in fact, it’s a fun-house mirror version of Ford’s 6R140 Torque Converter’s lockup mechanism. Ford’s 6R140 lockup mechanism was excellent in the fact that it locked up facing the stator, rather than the flexplate.

Extremely heavy duty transmissions such as the 10L1000, 6R140 and AS69RC feature converters with reversed or “backwards” lockup mechanisms for generic reliability, heat management and oil coupling reasons. It is a healthy improvement in durability for this progression in engineering to take place, however this does not make the unit perfect.

The reality is that the torque capacity of this lockup mechanism, though difficult to test due to variables, seems to die at virtually any power level above factory, OR when tire size is greatly increased without an appropriate regear. Trucks exceeding 500HP or who plan to tow extremely heavy will statistically not survive long. Fortunately, we do offer 2 different Billet Multi-Friction Torque Converters for those in trepidation of this issue.

Problem #2 - The Stator

The stator, the part inside the torque converter that controls stall speed, is incredibly frail and contributes to complications in heat management. This is an inferiority that Ford and moreso GM/Allison have been plagued with for years in the diesel community. Despite the inferiority of Dodge converters, they also have the most powerful stators that we have tested in factory form. As a result, anyone seeking to upgrade this torque converter must make modifications to the stator.

The solution here is multi-fold, the first thing one must do is identify a stronger material to manufacture the stator from. As a result, CNC Machined and often billet stators (depending on application) are used to prevent the common gyration, cracking or yaw that geometrically impact this items ability to operate reliably.

To make things simple, any 10L1000 or 10R140 torque converter with an unmodified OEM stator in place will be exceedingly more likely to fail. As a result, we do not use a stock stator in any of our 10L1000 Torque Converters. We prefer to precision machine the stator of the converter, allowing us to have omniscient control over stall speed.

Problem #3 - Functional Issues Caused by Added Power

This brings us to a subsequent point, the friction elements. As stated previously, this is an exceptional design, however, the diesel community is no stranger to tuning platforms like EFI Live or EZ Lynk being used to enhance economy, power output and functionality. As a result, this converter is often asked to withstand more power than it was ever engineered to withstand, forcing the aftermarket to step in.

Due to this, all customers seeking to even perform a tune to this truck should understand that the clutch and steel stack-ups inside the transmission are generally only sufficient for the amount of torque the truck created from the factory and virtually nothing more. This necessitates the implementation of billet pistons, billet reaction plates and redesigned clutches and steels that are appropriate in dimension and quality to fulfill the needs of the consumer.

Lastly, on the topic of friction elements and torque converters as well as how they are challenged by added power, the 10L1000 and 10R140 have a unique ability to achieve lockup as early as 1st gear to help regulate heat. Fluid coupling produces about 70% of the heat generated by this transmission depending on barometrics, stall speed, drivetrain and other thermostatic factors. This stated, it is imperative that a torque converter is designed with the priorities of longevity, heat management and power capacity.

Modifications such as the ones described above, allow us to manufacture a unique torque converter that accomplishes these 3 goals in beautiful trichotomy. The diagram below can be used to identify the different converter parts appearance as well as the physical location of other clutch packs within this transmission.

Problem #4 - The “E” Clutch Hub

This is a tricky one. Deep inside the transmission is the “E” Clutch is active in first, third, fifth, sixth, seventh, eighth and ninth gear, making it the most used and abused clutch in the transmission by any logical metric. This clutch is colored in red closer to the back of the transmission in the diagram above.

As with all Ford TorqShift designs dating back to the late 80’s, the aluminum castings used to make components like this are prone to aggressive wear and irreparable damage. In fact, the majority of 10L1000’s and 10R140’s that we have seen with added power demonstrate substantial wear to this specific component.

As a result, one would find it illogical not to make this part out of Steel rather than weaker but lighter Aluminum. The factory is making more and more parts out of aluminum in the interest of minimizing negative inertia, a physical force that acts against the combustible propulsion generated by the functional cycling of the motor. The problem is that most things being made out of Aluminum are now only able to survive their own warranty period at stock power.

That stated, it is easy to see how making this component out of Steel is an unobjectionable decision. Something that should also be taken into consideration is the insufficient clutch volume of this component. This unit holds 5 clutches from the factory, but 6-7 are needed for any truck with added power or the intent of high mileage operation.

A custom machined steel “E” Clutch Hub allows one to address both of these problems simultaneously by converting to a stronger material as well as enhancing the design to add torque capacity and heat dissipation through added frictions and steels.

The result when implementing both in the same transmission is smooth, crisp and predictable shifts that can be trusted for years to come, regardless of what’s behind you or in front. That makes this a critical inclusion in a properly built 10L1000 transmission.

Problem #5 - The OEM Oil Pan

This is a brief inferiority, but it is worth discussing. These pans, much like the rest of the transmission industry, are made out of stamped metal that is heated and then cooled naturally to retain it’s shape. This is a problem for many reasons:

- It does not allow for a proper mating surface where the pan mates to the case because there is no precision flattened surface on the pans side.

- The pan is incredibly thin, and cannot safely withstand any rugged use safely. Off-Roaders should beware of factory pans.

- The pan is nowhere near large enough, this transmission needs more fluid to operate at peak performance and cool temperatures, the factory pan inhibits this by negating a potential safe increase in oil. This forces the transmission to run hotter than it should, drastically effecting the lifespan of the friction elements inside the transmission and torque converter.

- The pan does not have sufficient surface area to exhaust heat properly, heat goes to where there is a lack of heat. This is because heat is a form of energy. Increases in surface area enhance a metal’s ability to release heat into the environment around it.

Problem #6 - The High Pressure Oil Pump

The oil pump of the 10L1000 transmission is vaguely similar to late model TorqShifts in the sense that it’s impeller hub (pictured below) is splined to mate directly into the pump. The impeller hub of the torque converter is the component on the back of the converter that sits in the pump to spin the central pump gear that creates pressure. This is designed to better distribute torque load across the pump and impeller hub to minimize failures.

This is a plus, however the pump is forced to eat clutch material and steel particulates regularly by an inferior converter and combination of clutch stack-ups. The end result is that in a factory transmission, this pump is destined to a shortened lifespan due to indirect factors that effect it’s health. Stronger clutch packs that are designed for the application, rather than struggling to suffice their obligations, contribute to a much longer lasting high pressure oil pump in the Allison 10L1000.

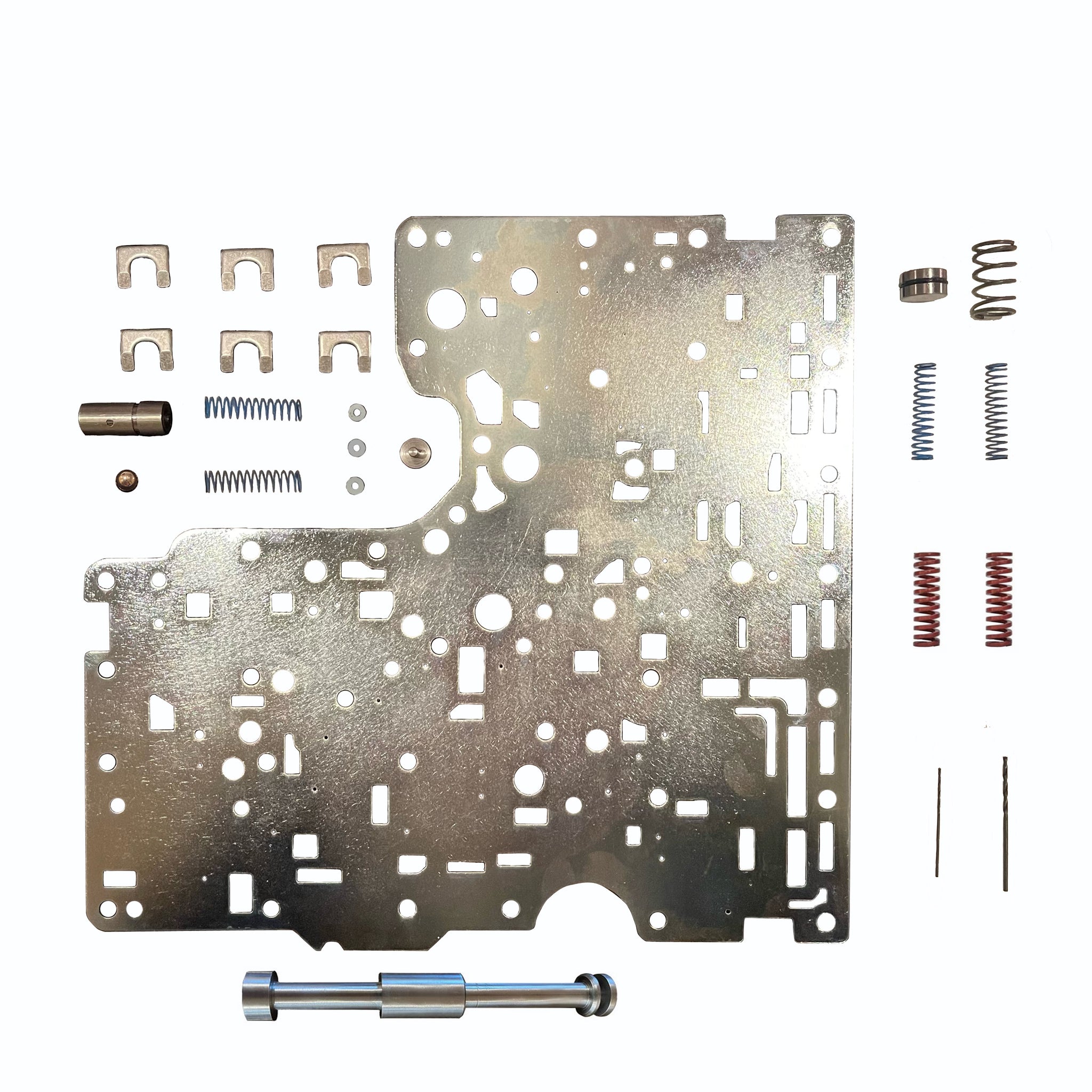

Problem #7 - The Valve Body

Ford has been known to engineer products like this using ZF based valve bodies in the past. However, this time it appears to be a more proprietary design. The valve body in this transmission suffers from the same wear complications that the high pressure oil pump does. However, there is the added complication of the relationship between the valve body and the electronics of the transmission.

Once a valve body has begun to wear in this transmission, there is absolutely no regenerative solution. Galvanic wear takes a violent toll on this valve body and this process starts the day it leaves the dealership. The solution here is to ensure, as with the pump, that the valve body is given the proper pre-requisites for success from day one; a properly built transmission that will not prolifically shed particulates of matter through these sensitive hydraulic components.

Problem #8 - The Electronics

As the most complicated transmission ever fitted to the DuraMax lineup, this transmission comes with one input speed sensor, two intermediate speed sensors, one output speed sensor and an internal mode switch, all attempting to function together. This leaves great room for complication, especially in a unit as computer-intensive as the 10L1000.

This is not a prolific issue that warrants an reinventing of the wheel, but it is worth understanding the electronically intense unit that this is. If we have any critical advice for the electronics of the 10L1000, it is the same advice that we tender on any transmission:

Use only OEM electronics during any remanufacturing of the transmission!

We are no stranger to cheaper, imported, aftermarket electronics; in fact, we’ve tested them in multiple different environments to collect data on their reliability. Although we received very inconclusive results as this would take years to effectively study, the general correlation is that non-OEM electronics had a disproportionate probability of being bad out of the box, as well as failing within the first 12 months of use. That stated, we only use OEM electronics in all transmission remanufacturing that we perform.

Frequently Asked Questions about the 10 Speed Allison 10L1000 Transmission:

Q: Is the Allison 10L1000 a good transmission?

A: Known as a less-than-reliable unit, the 10 Speed Allison 10L1000 transmission is a fertile breeding ground for a variety of problems. This includes but is not limited to: Valve body crossleakage, burnt clutches, damaged clutch hubs, stripped shells and much more.

Q: Is there TCM Tuning for the 10 Speed Allison 10L1000 transmission?

A: Yes! The 10 Speed Allison 10L1000 can be easily tuned to request different shift points, different lockup protocol and various other functional changes. However, most of these parameters do not need to change for the transmission to work optimally. Mechanical upgrades are significantly more important.

Q: What is the lifespan of a 10 Speed Allison 10L1000?

A: Although there are many variables, the 10 Speed Allison 10L1000 transmission lasts an average of 100,000 to 150,000 miles in unmodified trucks with average applications. Trucks with larger tires, tuning, emissions delete systems and other aggravating factors usually fail much sooner. Transmissions with religious maintenance routines that are used largely for highway miles can last longer in some cases.

Q: What is the best upgrade for a 10 Speed Allison 10L1000 transmission?

A: The single most important upgrade someone can perform on a 10 Speed Allison 10L1000 transmission is a valve body. The valve body is where the overwhelming majority of their problems begin, and can yield huge benefits to any application. All Allison 10L1000 transmissions, regardless of application, should have one of our upgraded valve bodies.

Q: What are the service intervals of a 10 Speed Allison 10L1000 transmission?

A: It is our advice that this transmission is hot-flushed and a complete fluid and filter change is executed every 25,000 miles on average. Extraordinary applications may want to perform these services more frequently, whereas highway exclusive applications can safely push a bit further between services.

Conclusion to the 10 Speed Allison 10L1000 Transmission:

The 10L1000 is a long awaited and critically needed progression in Allison’s complex and innovative transmission lineup. As the latest entry in this saga, it’s expectations are tall and it unfortunately cannot survive all of them. As a result, we have researched and collected data on this transmission to the best of our ability, in the interest of manufacturing the highest quality product. To find more reading on our Allison 10L1000 catalog, see here:

>>> Allison 10L10000 Transmissions, Rebuild Kits and Parts

For further information on the 10L1000 transmission or any transmission for which we offer support, contact one of our experts!

Comments (22)

14k on my 10 speed Allison and getting torque converter replaced

my 2020 gmc 3500 serriea 10L 1000 transmission leak. the dealer has replace the torque converter and tit leaking worse than before, how do i get them to replace the transmission? It took 3 weeks before just to replace the torque convertor.