Table of Contents:

- Introduction to the AS68RC Transmission

- Aisin Seiki AS68RC Product Resources

- Popular Transmission Information Resources

- In this Drivetrain 101, we will be addressing

- A Brief History of the Aisin Seiki AS68RC Transmission

- How the Aisin Seiki AS68RC Transmission Clutch Packs Work

- Problem #1 - The Torque Converter

- Problem #2 - The High Pressure Oil Pump

- Problem #3 - The Valve Body

- Problem #4 - The K2 Clutch Hub

- Problem #5 - The K2 Clutch Assembly

- Problem #6 - The Rear Carrier Bearing/Stator Support Assembly

- Problem #7 - The Internal Wiring Harness

- Problem #8 - The Oil Pan

- Problem #9 - The Bushings (You read that right!)

- Conclusion to the AS68RC Transmission

Introduction to the AS68RC Transmission:

As the inventors of the famous Project Carbon AS68RC High Pressure Valve Body Upgrade Kit, we at Next Gen Drivetrain are proud to be at the forefront of the AS68RC market. If you own a Ram or Isuzu truck featuring the infamous AS68RC, you likely know Next Gen Drivetrain as the best place for uparmored AS68RC transmissions and parts, designing unique parts and building them for a diverse spectrum of applications. All too often, we are approached with question after question about this highly complicated transmission; ranging from what fails to why and how. Fortunately, we've fulfilled this demand with an installment in our popular Drivetrain 101 series. If you've done any research on the Aisin Seiki AS68RC Transmission, you likely have already learned the following three things:

If you've done any research on the Aisin Seiki AS68RC Transmission, you likely have already learned the following three things:

>>> View our AS68RC Transmissions & Parts Catalog Here!

- Virtually nobody knows anything about this transmission at all, nevermind offering aftermarket support for it (except the audacious nerds at Next Gen of course).

- The transmission is exceedingly unreliable by design. The Aisin Seiki AS68RC transmission is notorious for sordid oil pump and valve body problems that often leave the core transmission unsalvagable, even despite often being in operating condition when they're removed from the truck.

- You will see that the transmission is on the expensive end of the spectrum to properly build, regardless of your goals. This is because of a combination of frequent core damage as well as the extensive amount of modification necessary to have a "Lifetime Transmission" emplaced in an Aisin Seiki AS68RC truck.

>>> View our AS68RC Transmissions & Parts Catalog Here!

Now, with this all stated, what is the solution? This installment in our popular Drivetrain 101 series will address all of this and more.

Aisin Seiki AS68RC Product Resources:

- AS68RC Transmissions

- AS68RC Torque Converters

- AS68RC Rebuild Kits

- AS68RC Valve Bodies

- AS68RC Parts

Popular Transmission Information Resources:

- Top 5 Benefits of an Upgraded or Built Transmission

- Calculating Torque Multiplication Factor, Why is it So Important?

- Top 5 Ways to Extend the Life of a Factory Transmission

In this Drivetrain 101, we will be addressing:

- The most popular failures we witness on the Aisin Seiki AS68RC transmission

- Its capabilities (or lack there of) in reference to TCM tuning and shift/lockup protocol modification

- The strengths (believe it or not, there are a few!) of this transmission

- Footnotes for Dodge AND Isuzu owners

And much, much more!

>>> View our AS68RC Transmissions & Parts Catalog Here!

A Brief History of the Aisin Seiki AS68RC Transmission:

In production year 2006 (model year 2007.5 to specify), the 6.7L Cummins was released. This motor brought forth noticeable increases in power and capability, rendering the half century old 727 Torqueflite platform (most recently the 48RE Transmission whose Drivetrain 101 installment can be found by clicking here) unusable for the newfound application.

As a result, Chrysler devised two alternatives. The G56 Transmission remained an available option, but both automatics were anew. First, was the 68RFE Transmission whose Drivetrain 101 installment can be found by clicking here! The 68RFE was featured in all 2500 and 3500 models with a standard bed of some sort, essentially NON-Cab & Chassis configurations. Simply put, if you do not have a Cab & Chassis configured truck from the factory, you do not have an Aisin Seiki AS68RC Transmission.

>>> View our AS68RC Transmissions & Parts Catalog Here!

*Curious how the AS68RC and 68RFE compare? Check out their comparison here!*

Alternatively, if you had a Ram 4500/5500, or Cab & Chassis configured 3500, you will have an Aisin Seiki AS68RC Transmission (we offer our condolences for your tragedy). This transmission is NOT made in-house contrary to common belief. In fact, Aisin Seiki is the "Allison" of Toyota. These transmissions are most frequently found in Isuzu and Mitsubishi box trucks, Toyota Land Cruisers, and various Volvo passenger vehicles.

By contrast, the 68RFE is an inflated 89' Plymouth Caravan transmission that was converter to RWD, so one should not think that would have been the saving grace here. In production year 2012 (model year 2013), the AS68RC was retired for it's more modern frat, the Aisin Seiki AS69RC Transmission. Should you have an AS68RC, as with truly any transmission, you will face a unique host of problems and catalyzing factors that contribute to expensive and unforeseeable failure in this unit. Below, we will analyze each of these failure points and how they can be resolved.

>>> View our AS68RC Transmissions & Parts Catalog Here!

*Footnote for Mitsubishi/Isuzu AS68RC Trucks* - The Mitsubishi and Isuzu AS68RC was slightly different than the Dodge rendition. The differences are in the valve body's hydromechanical calibration and can be differentiated by these numbers on the transmission valve body itself.

How the Aisin Seiki AS68RC Transmission Clutch Packs Work:

To recognize some basic operating facts about this transmission, the Aisin Seiki AS68RC transmission is a 6 Speed Automatic computer controlled transmission, with lockup capable torque converter. In the drive position you will have 6 forward speeds. When pressing the “tow haul” switch or “O/D off” switch on the end of the shifter handle once you will omit 6th gear and have later upshifts into all other gears. Press the switch a 2nd time and you will omit both 5th and 6th gears. Pressing 3rd time will give you full upshifts of all 6 gears again.

>>> View our AS68RC Transmissions & Parts Catalog Here!

Every transmission has unique qualities in terms of how it calculates shift behavior, how it responds to solenoid inputs and more. The Aisin Seiki AS68RC is no different. Something that is critical in understanding the AS68RC is understanding it’s clutch application chart. For this purpose, we should examine this information below:

I want to take a moment to explain how this chart works and what it represents. This unit has a similar clutch application chart to most 6 speed transmissions, featuring an underdrive clutch (K1) which applies in first through fourth, and applies on top of the overdrive clutch (K2) to create a 1:1 drive ratio as no direct drive clutch pack exists.

>>> View our AS68RC Transmissions & Parts Catalog Here!

By contrast, K3 and B1 function as rational clutch packs that pertain to the mechanical operation of a single UD/OD or double UD/OD drive state. What does this mean? These clutch packs are used to control WHICH of the gearsets is brought on to activate the gear you desire. Without clutch packs like these, you'd be limited to 3 and 4 speed transmissions. They allow us to access additional gears by offering TWO underdriven gears and TWO overdriven gears rather than just one. Allison, 68RFE, 6R140 and more all use a similar pattern.

And like those units, it has the same clutch related issue; compromising the OD (K2) clutch pack. Though we will speak more at length later, the K2 clutch pack is the most frequently damaged in the entire unit. Fortunately, we offer many proprietary upgrades to prevent this from transpiring, such as the Aisin Seiki AS68RC Project Carbon Billet K2 Hub Assembly. (Pictured Below)

>>> View our AS68RC Transmissions & Parts Catalog Here!

Alternatively, manual 3 will allow only 1st, 2nd and 3rd gears and engine braking. Manual 2nd will allow only 1st and 2nd gears and engine braking. Manual low will give you low gear only and engine braking. This transmission is rated up to 26,000lbs of gross vehicle weight and has PTO capability. This unit also comes in both 2WD and 4WD configurations.

Further, the solenoids themselves have a very unique and complicated application chart that controls their operation. We have a clone of the OEM solenoid application chart for your informative convenience below:

>>> View our AS68RC Transmissions & Parts Catalog Here!

As you can see, the AS68RC is immensely complex. No attempt was made to simplify this transmission, especially electronically. The end result was a transmission that has tremendous operational capabilities, but simply suffers from it's own inherent complexity. Fortunately, Next Gen welcomes highly complicated drivetrain challenges. Now, we will observe the most prolific failure points in the Aisin Seiki AS68RC Transmission and how we permanently resolve them!

Problem #1 - The Torque Converter

This specific component could cash-in on it's own Transmissions 101 section, but we will compress it into a few paragraphs. The OEM torque converter is constructed in a very awkward way, but it mostly works; mostly. The AS68RC Torque Converter's lockup mechanism operates backwards, meaning instead of applying the torque converter clutch (TCC) against the cover, it applies against a backing plate that faces the transmission itself and uses the cover portion as an oil galley.

>>> View our AS68RC Transmissions & Parts Catalog Here!

Generally speaking, this is reliable. In fact, the confident and gallant ZF6HP26-based 6R140 Transmission from Ford does virtually the same thing. The issue is that the clutch pack splines into a very low quality, flimsy aluminum cage inside the cover that often snaps apart in something as simple as a stock truck with an exceptionally heavy towing routine. Adding any level of power is a death sentence to the Aisin Seiki AS68RC Transmission.

To assert what we do differently here, we will simply need to show you an exploded view of the AS68RC Torque Converter to elaborate. Allow us to itemize the failure points below, and our upgrade there-within or relevant notes for said component:

>>> View our AS68RC Transmissions & Parts Catalog Here!

#2 (Impeller Hub) - This component is known as the Impeller Hub, and is responsible for mechanically adjoining the pump to the torque converter. It's also a critical component for modulating the flow of oil into and out of the pump itself. These components fail due to cracking and rounding out. If you tow heavy, or have a tuner on your truck, you are at a dramatically increased probability of this failure over time. Our Chromoly solution ensures this to be a thing of the past.

#3/#10 (Pump/Turbine) - These components are responsible for augmenting the efforts of the stator assembly to facilitate the process of fluid coupling. We have witnessed multiple failures from ballooning of the torque converter to unsettlement of the associated impeller fins. Furnace brazing of these components is a permanent resolution and enhancement in operational benefit.

#9 (Stator Assembly) - This component is called the stator. Not only do we manufacture an entire line of custom AS68RC stators, they are hand-cut here in San Diego on a CNC Lathe. What does this mean for you? Perfect control of stall speed and operation! If you're unsure of what stall option would be most beneficial for you, please call us and speak to an expert. We'd be elated to offer support.

>>> View our AS68RC Transmissions & Parts Catalog Here!

#17 through #21 (Dampener Spring Assembly) - These springs are responsible for controlling the application of the TCC. By replacing them with springs of a higher seat and nose pressure, we enforce a firmer and more expeditious lockup process, negating many potential areas for clutch failure in this expensive torque converter.

#24 through #28 (TCC Assembly) - The Aisin Seiki AS68RC Transmission torque converter features 3 multi-sided friction elements with 3 steels and a backing plate, the sole issue is the low quality of the clutches themselves. It is easy to abhor these clutches for their low quality friction material, raw steel and tolerances. We offer an Alto G3 carbon graphite 6-Disk assembly in it's place.

#29 (TCC Apply Piston) - The component associated with this is called a "Molded TCC Apply Piston" and is notorious for flexion and overheating. The reason this happens is actually not the pistons fault, but the fault of inadequate oil travel in and out of the torque converter, as well as excessive internal converter pressure. Our stator negates this concern, as we speak of in item #9.

>>> View our AS68RC Transmissions & Parts Catalog Here!

#34 (Cover) - This is the cover itself, as you can see, there are a plurality of fins in place that the steels themselves must spline into. The AS68RC torque converter's unhealthily high stall speed causes the TCC to synchronize two wildly different speeds of component, generating complications in longevity and operation. By enforcing this cage and using higher quality clutches and steels in this clutch pack, we absolve ourselves of the issue of excessive wear or hard failure in this component. For our most aggressive applications, we replace the entire unit with a massive steel clone, permanently resolving all potential complications.

Sound like a nightmare? Fortunately at Next Gen, we have spent a tremendous amount of time understanding the cause for failure in this transmissions torque converter and how to resolve it. To view torque converter solutions for this unit, try exploring our AS68RC Torque Converters section!

>>> View our AS68RC Transmissions & Parts Catalog Here!

Problem #2 - The High Pressure Oil Pump

As a prodigal source of many Aisin Seiki AS68RC transmission problems, the AS68RC's oil pump operates very similar to how an LS Motor oil pump works. As such, it suffers from the same problem; disproportionate gear wear. What do we mean by this? Consider the following.

The AS68RC pump offers 2 pump gears, one larger and one smaller. They spin with the smaller inside the larger gear, and the smaller gear splining onto the impeller hub of the torque converter. The fundamental complication with this design is that it pushes the gears to the opposing direction of the pressure vent, causing it to wear excessively on the opposite portion of the pump.

>>> View our AS68RC Transmissions & Parts Catalog Here!

We can retard this process with high quality oil filtration, but that only offers us so much solace. Realistically, the pump is generally unsalvageable and will require replacement. The permanent resolution to this is treated and CNC machined pump gears that have a protective coating to prevent them from wearing the new pump out again, at any mileage. This is part of why our proprietary Formula One pump and valve body for the Aisin Seiki AS68RC Transmission has been and continues to be so successful.

It should also be noted that the transmission's pump is hydromechanically calibrated to the valve body using shims. As such, replacing the pump requires replacing the valve body simultaneously. These parts together are about $5,000 from the OEM, and are almost always bad in cores. This is the justifying factor for the rather large core charge on the AS68RC Transmission. This brings us to the proximal failure of this complicated transmission.

>>> View our AS68RC Transmissions & Parts Catalog Here!

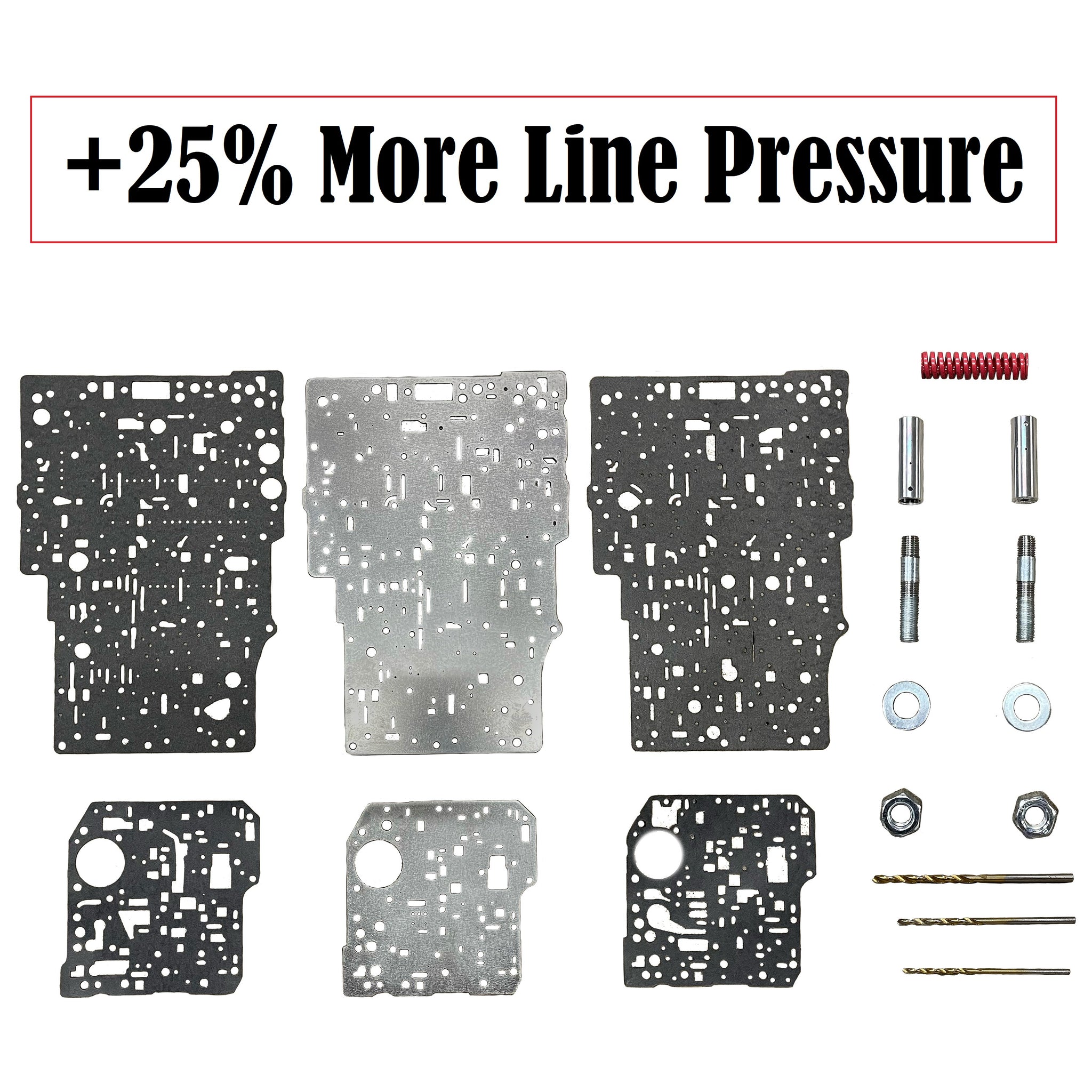

Problem #3 - The Valve Body

The Aisin Seiki AS68RC Valve Body is the Oil Pump's right hand friend, working cohesively with the pump to complete tasks issued by the trucks powertrain control module (PCM). The issue is as often, multi-fold. The AS68RC valve body contains various different accumulators and plungers that are overwhelmingly likely to seize and crossleak.

Also, the AS68RC valve body features a tremendous quantity of moving valves, whereas transmissions like the 68RFE have simply 3. This translates into more leak points, more seizure points and more potential hydraulic codes. The AS68RC's valve body's high complexity contributes to many of it's complications. In the diagram below, we can analyze the convoluted oil flow adventure this transmission embarks on to simply bring forth just one clutch pack.

>>> View our AS68RC Transmissions & Parts Catalog Here!

Confused? Don't worry, you're not alone and that's the problem. This transmission has overly complicated its lifestyle and billowed itself with countless additional tasks to complete even the simplest measure. As a result, longevity and operational reliability are greatly inhibited. To resolve this, we located the valves and plungers most likely to generate seizures and crossleaks and replaced them all, one by one, with alternatives engineered to absolve us of the problems said components cause. This includes but is not limited to the B1/B2 plungers, K2 and K1 accumulator springs and the separator plate itself.

>>> View our AS68RC Transmissions & Parts Catalog Here!

As a result, we are left with an exceedingly reliable valve body that that doesn't possess much ability to fail again. The valves that prolifically seize now offer sleeves and plungers designed to negate this as a possibility, and the accumulation design inferiorities that plague this unit and detract from longevity are also a thing of the past.

Problem #4 - The K2 Clutch Hub

This component is actually totally reliable in virtually every application BUT the heavy duty diesel trucks, due to the diesel vehicles all offering more torque, earlier in the RPM range, and weighing much more. You can learn more about this concept by reading our Transmissions 101 installment on Torque Multiplication Factors and how they effect transmission life. The K2 hub of the AS68RC (pictured in Billet earlier in the publication) is natively made of a stamped steel that is feeble and thin. By metric of comparison, the oil pan is also made of stamped steel. Would you trust that metal to hold the power of your truck?

>>> View our AS68RC Transmissions & Parts Catalog Here!

This hub has a very critical task, to synchronize in speed with the input shaft during the 3-4 upshift, suspending the mass of the truck AND load against it. This is why the problem disproportionately effects high GVWR applications (towing, hotshotting and utility beds). The way this hub fails is one of two. One way, it simply breaks apart rendering the transmission unusable. The other way is much more passive and dangerous.

The hub begins to wear and yield slowly each time the sharp K2 clutches dig into the soft and low-quality steel. In a truly stock application, this can generally be evaded, but those seeking to add any level of power or tow frequently should absolutely consider the additional Billet K2 Hub Assembly. The reason this is so scary is because the hub and transmission itself will actually work fine for some-time, occasionally hundreds of thousands of miles, just to fall flat on it's face randomly somewhere between fourth and sixth gear. Why? Because the K2 hub rounds out completely.

>>> View our AS68RC Transmissions & Parts Catalog Here!

If you look closely at the image below, you can see the factory hub beginning to be dug into at the splines. This is a 100% OEM AS68RC K2 Hub in an unmodified truck with about 70K miles, as a metric of comparison. If this customer continued driving this truck as such, they'd have eventually totaled the transmission and the core in most probability, regardless of their driving and use habits or power.

Problem #5 - The K2 Clutch Assembly

You guessed it, just as the K2 hub is a malign pile of waste, as is the clutch pack and associated componentry responsible for it's use. The factory Aisin Seiki AS68RC Transmission offers 5 K2 clutches. When replaced with high quality upgraded friction materials, it can generally capacitate about 25% more torque than the factory unit. To exceed figures like this however, additional frictions and steels will be necessary.

>>> View our AS68RC Transmissions & Parts Catalog Here!

At Next Gen, and exclusively in our Street AS68RC and it's associated transmission rebuild kit, the most durable AS68RC available, the K2 clutch pack is completely redesigned. In doing so, we add an additional 20% in total friction volume as well as an additional steel element to aid in heat release. This, when augmented by high quality materials, increases the torque capacity of the transmission by approximately 48-53% depending on some additional factors such as oiling. Nonetheless, this is a MASSIVE improvement!

In addition, a CNC machined apply piston and backing plate are totally reengineered to enable this clutch pack to exist in the otherwise plagued AS68RC. Whilst installing this dramatically stronger clutch pack, we also enjoy using a stronger snap ring to keep this assembly in place. With all of these things in place, the K2 clutch assembly becomes massively overbuilt ensuring peace of mind for the future of your Aisin Seiki AS68RC transmission!

>>> View our AS68RC Transmissions & Parts Catalog Here!

Problem #6 - The Rear Carrier Bearing/Stator Support Assembly

Despite being subcomponents of the pump, this specific assembly is prone to it's own issues and should be assessed separately. The OEM Stator support often dies when the needle bearing that supports the input shaft comes apart. It's made from paper-thin aluminum and can easily be overspun or overstressed. We use only updated versions with a revised roller carrier assembly that has never been seen to cause this problem, ever.

In addition, we've found various applications that have the capacity to harm the stator support. Specifically during the 3-4 upshift, as this asserts immense amounts of stress on the converter. The twisting force is quite violent and can render this shaft damaged or even physically broken. Although this is uncommon in lower power applications, the bearing update is critical for all, and those intending to add power should see this billet shaft as a must for their build.

>>> View our AS68RC Transmissions & Parts Catalog Here!

Problem #7 - The Internal Wiring Harness

This transmission was manufactured with two different internal wiring harnesses. One was a 10-Pin style connector, used in the 2007.5 through 2010 model years of truck. The other is a 12-Pin style connector, offered in the later 2011 through 2012 model years of truck. The additional two pins are a load and ground for additional electronic function of the valve body. You can think of this analogically as a home where someone installed a 6th electric ceiling fan in it when it originally had only 5, it will simply need some additional wiring to add the sixth ceiling fan to a home that originally had five.

The issue with the internal wiring harness is that it crimps, and succumbs to something known informally as the "paperclip effect." When bending a paperclip back and forth, it eventually breaks like nothing. The same thing occurs to the copper wires inside the low quality OEM internal wiring harness. Fortunately the OEM has since updated the wiring harness to a more reliable alternative. The updated OEM AS68RC Wiring Harness can be found here.

>>> View our AS68RC Transmissions & Parts Catalog Here!

Here at Next Gen, 100% of our AS68RC transmissions are built with this updated harness in place. In fact, we replace ALL of the AS68RC electronics, inside and out, with OEM replacements. If there is a successor to the original part number, that more modern part will be what is in place in our product. This is unique to Next Gen because we had to approach Mopar corporate with a distribution company by our side to get them to mass-import OEM Aisin Seiki electronics. What does this mean? Next Gen is the only company offering a true, complete rebuild on the Aisin Seiki AS68RC OR AS69RC transmission.

Problem #8 - The Oil Pan

As with most oil pans, ground clearance was prioritized over functionality. Fortunately, the diesel community is generally exempt from this concern. As a result, it is strongly recommended as well as standard in all of our complete Aisin Seiki AS68RC Transmissions to receive an extra deep transmission oil pan.Our pan is deepest on the market, capacitating an additional 4.5 quarts over stock!

>>> View our AS68RC Transmissions & Parts Catalog Here!

Problem #9 - The Bushings (You read that right!)

Like most gas-native piles of shit, the Aisin Seiki AS68RC Transmission features incredibly soft babbitt material bushings that suffer from dismal longevity. The issue with this material is that it generally cannot survive more than 150,000 miles, even in perfect filtration. Granted, many people surpass this mileage, but many of those people's cores experience excessive wear beyond what replacement of bushings can replenish. These people suffer in their core charge, and hence we highly urge Aisin Seiki owners to build the transmission BEFORE any excessive mileage.

At Next Gen, our standard of practice is a set of true Bronze bushings. By manufacturing bushings out of bronze, their capacity to wear over time is massively minimized. In fact, bronze bushings have no advertised lifespan, making them a definitive and necessary option for any proper AS68RC rebuild.

>>> View our AS68RC Transmissions & Parts Catalog Here!

Conclusion to the AS68RC Transmission:

As one can see, the Aisin Seiki AS68RC Transmission is plagued with a variety of mechanical, hydraulic and electronic ailments. Together, they make an incredibly untrustworthy transmission. However, once properly built, the AS68RC can be a formidable, durable and multi-talented high performance diesel transmission. Does this publication still leave you with questions? Feel free to call in and speak to one of our experts today!

Comments (4)

Engine light comes on and it shift down to second and when you read code it says high-pressure solenoid stuck

2008 dodge ram 4500 reverse works ,transmission trying to take off in 3rd gear

I am looking for aisin as68rc valve body

i am from south africa – do you deliver here

also how much is it

Hey there I just bought a 07 3500 with the aisin and it will not shift into any gear, I have a little bit of reverse if I really step on it, but for the most part absolutely nothing can you help me

Thanks