Table of Contents:

- Introduction to the Ford 10R140 Transmission

- In this Drivetrain 101, we will be addressing

- Ford 10R140 Product Resources

- Popular Transmission Information Resources

- A Brief History of the 10R140 Transmission

- How the 10R140 Clutch Packs Work

- Problem #1 - The Torque Converter

- Problem #2 - The Valve Body

- Problem #3 - The Oil Pump

- Problem #4 - The "E" Clutch Assembly

- Problem #5 - The Oil Pan

- Problem #6 - The "B" Clutch Assembly

- Problem #7 - The C-D-F Drum Assembly

- Frequently Asked Questions about the 10-Speed Ford 10R140 Transmission

- Conclusion to the Ford 10R140 Transmission

Introduction to the Ford 10R140 Transmission:

As the inventors of the famous Project Carbon 10R140 High Pressure Valve Body Upgrade Kit, we at Next Gen Drivetrain are proud to be at the forefront of the 10R140 market. If you own a late model Ford Super Duty, you likely know Next Gen Drivetrain as the best place for uparmored 10R140 transmissions and parts, designing unique parts and building them for a diverse spectrum of applications. All too often, we are approached with question after question about this highly complicated transmission; ranging from what fails to why and how. Fortunately, we've fulfilled this demand with an installment in our popular Drivetrain 101 series.

It should be noted that this transmission is the fraternal twin to the Allison 10L1000 Transmission, fitted to the corresponding years of DuraMax diesel. This product was engineered as a joint venture between Ford and GM (General Motors). They are slightly different, in that Allison owns multiple intellectual property items that they've implemented to their version of this transmission, as did Ford. Because of this, they are not identical.

Our goal is to educate, inform and support the Ford Super Duty market with high quality data and facts about their transmission. As transmissions and vehicles in general become ever more complicated, it's important to educate yourself on how these mechanisms operate. If you want to become an expert on the Ford 10R140 transmission, this Drivetrain 101 is for you!

In this Drivetrain 101, we will be addressing:

- The most popular failures we witness on the 10R140 transmission

- Ways to get the most out of your transmission

- The strengths (believe it or not, there are a few!) of this transmission

- Resources for relevant updates and upgrades

And much, much more!

Ford 10R140 Product Resources:

- 10R140 Transmissions

- 10R140 Torque Converters

- 10R140 Rebuild Kits

- 10R140 Valve Bodies

- 10R140 Parts

Popular Transmission Information Resources:

- Top 5 Benefits of an Upgraded or Built Transmission

- Calculating Torque Multiplication Factor, Why is it So Important?

- Top 5 Ways to Extend the Life of a Factory Transmission

A Brief History of the 10R140 Transmission:

Prior to 2020, the 6.7 Power Stroke came with the respectable 6R140 transmission. Unfortunately, as the ferocity of these motors increases, the 6R140 transmission quickly became ill equipped for the job. Because of this, Ford (and GM) had to pursue a new option. Due to their massive capital reserve, Ford was able to engineer their own transmission just as they did with it's predecessor.

After years of research and development, out came the 10R140 transmission. The new 10 Speed is able to hold considerably more power, using more robust components internally. Additionally, it is designed to keep the motor inside a narrow operating range to favor efficiency. 10 Speed transmissions, in general, largely just exist as an appeasement to the EPA. It could easily be argued that a stronger 6R140 would have easily sufficed.

At this time, there is no forseeable successor to the 10R140 transmission, it is likely to stay with us for the next few years. But, despite it's various enhancements over it's predecessor, the 10R140 transmission is not perfect. In fact, many people experience a rapid decline in transmission health with so little as 35" tires (sorry Tremor guys), nevermind removing emissions components or using a tuner. Although we love power as much as you do, we must be sober about the fact that power leads to broken transmissions much sooner. Fortunately, we will discuss how to resolve this later in the study.

How the 10R140 Clutch Packs Work:

Like nearly all electronic transmissions, the 10R140 transmission uses a shift map using various factors such as engine load and accelerometer input to calculate shift decisions without your input. Very similar to it's Allison counterpart, the 10R140 uses a form of adaptive shift protocol to optimize for smooth shifts. The onboard computer is constantly trying to advance or delay solenoid activation to support this goal.

Here, we can see a solenoid application chart. As one could see, there are MANY different solenoids in this transmission, all designed to operate in a complex and cohesive fashion. Naturally, this intensely complicated system can be prone to prolific electrical issues as well as valve bore wear issues, largely because of how many of them there are. Many clients report clunky, poorly timed or "confused" shift behavior as these problems present.

As a clutch to clutch style transmission, this means that the 10R140 does not use any bands, servos, levers, anchors or struts to activate any of it's functions. This is not necessarily a benefit or a drawback, but rather just a useful piece of information. Band & Servo style units were discontinued years ago due to their general inability to be electronically controlled. As we have all seen over the past years, OEM's are eager to electronically control transmissions. Now that we've learned about these foundational facts, we can analyze the problems of the 10R140 transmission and how to resolve them.

Problem #1 - The Torque Converter

Similar to the Allison 10L1000 transmission, the OEM torque converter is very stout in some ways, and very unprepared in others. The impeller hub, which is the piece that splines into the oil pump, is massive and very unlikely to break. Granted, it's not invincible, it's just stronger than many historical converters manufactured by Ford. We do offer a billet CNC machined hub on all of our torque converters, so this concern is nil with our product.

More prolifically, the converter clutches fatigue, flex and burn over time. They're quite fine on day one, but notorious for longevity issues. It's almost identical to the 6R140 Transmission in terms of the torque converter lockup clutches and how they work. To some consolation, the 10R140 is a line pressure monster, producing ample pressure to hold the clutches together assuming no other collateral failures take place.

Additionally, the OEM stator, the component responsible for controlling stall speed, is absurdly high stall. This is because stators have a notable impact on idling emissions, something the EPA is deeply concerned about. To the benefit of our consumer, we don't give a shit about the EPA. Our priority is on reliability, functionality and driving dynamics; things relevant to you as the owner of the vehicle.

Lastly, and as a collateral effect of the stator, the OEM converter escalates average operating temperature (AOT) by a considerable margin because the large allowable difference in speed between the motor side and the input shaft side of the converter is so immense. This generates huge amounts of thermokinetic energy, a chemical reaction producing heat. Heat is a silent killer in the transmission world, and detracts from the longevity of any transmission.

Problem #2 - The Valve Body

As with many transmissions, the 10R140 transmission's valve body is a huge cause of it's demise. Valve bodies are naturally complicated hydromechanical mechanisms with a huge concentration of moving parts and electronics. This makes them probable targets for internal crossleakage, solenoid failure and other similar problems that are notorious for cooking transmissions to death.

Firstly is the pressure solenoids inside the valve body. There are many of them as nearly all functions of this transmission are controlled by a switch or solenoid. As with most mechanisms, more moving parts means more things that can break. Generally, these solenoids are reliable, however they are often victimized by internal crossleakage inside the valve body that puts undue stress on the electronics by trying to push them on when the onboard computer believes they should be closed, or vice versa.

Additionally, the valvetrain inside the valve body is quite abundant, featuring dozens of moving parts. Every valve is a potential leakpoint. This would not be of concern if the transmission's valve body featured steel valves or anodized protective layers on the exterior of said valves, but unfortunately they are not. The valves are manufactured out of a low cost aluminum alloy designed to minimize cost at volume, leaving them susceptible to bore wear over time.

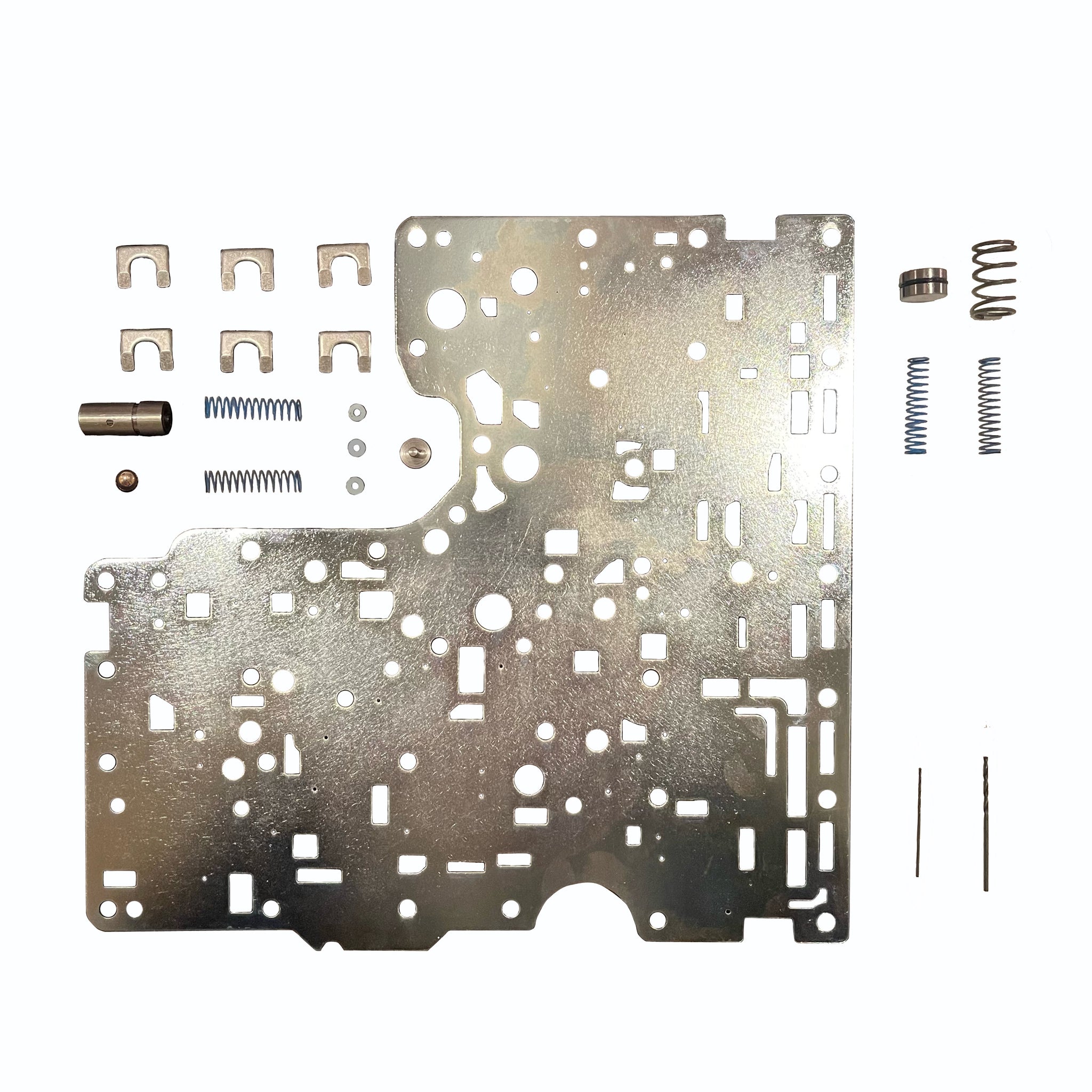

Further, the separator plate inside the valve body does not favor fast and efficient shifts. In fact, the separator plate contributes to many "sloppy" shifts by featuring unfavorable oil geometry when oil is trying to reach oncoming clutch packs. We expedite oil flow into oncoming clutches by making substantial modification to the OEM separator plate. To be fair, the OEM separator plate is rather thick and difficult to flex, but is inferior in other ways as mentioned. This makes modification of the OEM plate the most favorable way to ensure reliability as well as peak operability.

Problem #3 - The Oil Pump

Much akin to the Allison 10L1000 transmission is the 10R140 transmission's oil pump. The high pressure oil pump inside this transmission is incredibly complicated for no visible reason. It features dynamic veins and a rotating wheel driven by a steel gear with it's own filter. This design is generally reliable but requires abundant filtration to maintain said reliability, making regular service important.

In terms of failure, the OEM transmission tends to shed a large amount of friction material over time due to the low quality friction elements used from the factory and the intense amounts of clutch drag they suffer from due to their slow engagement and sloppy shifts. This naturally exacerbates and accelerates the wear issue of the OEM oil pump in unmodified 10R140 transmissions.

In addition to this, the 10R140 oil pump is notorious for losing oil pressure at the top end as this problem begins. This causes the transmission to shift erratically or sloppily under full throttle or with loads being towed. There beyond, these transmissions rely on oil pressure to calculate their shift behavior, contributing to tremendous confusion of the onboard computer whilst adapting to your driving patterns. This is one of many reasons the factory 10R140 transmission's shift strategy is so unpredictable.

Problem #4 - The "E" Clutch Assembly

As the commonalities amongst the Allison 10L1000 and the Ford 10R140 transmissions grow, we must mention the "E" clutch assembly. Although this clutch assembly does not have the highest torque multiplication factor, it does have a rather high one as it is used in most overdriven gears. The reason it is so quick to fail is because of a combination of this and the fact that the clutches are rather small in surface area.

Similar to the reason a car's smaller rear brakes do not provide as much stopping power as the larger front brakes, small friction plates offer less synchronization power than large ones. As a result, the "E" clutch assembly is disadvantaged from the factory. Granted, the OEM is not incentivized to provide over-built transmissions to the consumer, but rather transmissions that are low cost to produce and generally sufficient to see customers to the end of their warranty period providing they do not modify or overuse the vehicle.

Fortunately, we use a host of modifications to the valve body to enhance oil pressure to the "E" clutches as well as modify the separator plate to bring these clutches on much faster. The decrease in synchronization time enhances both shift quality AND longevity. It is unfortunate that the OEM did not care to provide benefits like this to the consumer.

Problem #5 - The Oil Pan

As an expensive 10 speed transmission, it is exceptionally important to maintain low oil temperatures to preserve the longevity of the transmission. From the factory, the OEM saves money by stamping the oil pan out of thin plastic using a mold and a special tool to provide accurate shape. This is never optimal, but certainly does not endorse a healthy transmission for heavy duty applications or long term use.

In fact, the OEM oil pan is so lacking in volume that a variety of transmission pan manufactures have added in excess of a gallon to the oil volume of this transmission. Due to the obvious nature of this upgrade, it is standard on ALL Next Gen Drivetrain 10R140 transmissions to contain a cast aluminum deep pan.

Another lost benefit when operating with an OEM oil pan is the lack of structural support to the case. Cast aluminum deep pans function as a "girdle" that supports the case to prevent flexion, greatly decreasing the potential for a broken case. Although broken cases are not very common to this transmission, it does exist and should be noted. A cast aluminum deep pan virtually eliminates this concern.

Problem #6 - The "B" Clutch Assembly

As the clutch pack active for 8th, 9th and 10th gear, the "B" clutch assembly features the greatest torque multiplication factor of any clutch pack inside the 10R140 transmission in most conditions. Much as the "E" clutch assembly suffers from inadequate apply pressure and inadequate oil feed rates, so does the "B" clutch assembly.

The "B" clutches are intermediate in size and would certainly be successful with access to better shift strategy and oil geometry, but unfortunately, the OEM does not provide this. The oil feed orifice inside the OEM separator plate is physically larger in Next Gen 10R140 transmissions, giving this clutch pack a far better chance at life.

To augment these efforts, the pressure regulator valve spring is also changed to require greater oil pressure before venting. This means more oil reaches the clutch pack, in a more timely fashion, tendering the support necessary for this transmission to endure the use of a more powerful or heavily used vehicle. Although all clutch packs are enhanced in some way in our product, it is important to highlight clutch packs such as "B" which are exceptionally at risk.

Problem #7 - The C-D-F Drum Assembly

Perhaps the most common problem we encounter, tied with valve body failure, is the bushing of the C-D-F drum assembly being forced out of place by excessive heat and pressure. This deprives half of the transmission of fluid pressure, causing near instantaneous failure. This problem is exacerbated by large tires, added power, frequent towing and many other things, although not partaking in these activities does not save you either.

We are proud to say that we resolved this issue almost immediately the same way we did in the smaller 10R80 Transmission. There are 2 necessary solutions to prevent this problem, both of which are standard in all 10R140 transmissions we offer.

Firsly, we increase the lubrication pressure in this valve body, the oil used to keep the transmissions inner workings cool, by 300%. This helps regulate the extraordinary heat that causes this bushing to travel in the first place. Secondarily, we machine a lip into the C-D-F drum assembly to keep the bushing in place regardless of circumstance. This problem has NEVER been recorded in a Next Gen Drivetrain product.

Frequently Asked Questions about the 10 Speed Ford 10R140 Transmission:

Q: Is the Ford 10R140 a good transmission?

A: Known as a less-than-reliable unit, the 10 Speed Ford 10R140 transmission is a fertile breeding ground for a variety of problems. This includes but is not limited to: Valve body crossleakage, burnt clutches, damaged clutch hubs, stripped shells and much more.

Q: Is there TCM Tuning for the 10 Speed Ford 10R140 transmission?

A: Yes! The 10 Speed Ford 10R140 can be easily tuned to request different shift points, different lockup protocol and various other functional changes. However, most of these parameters do not need to change for the transmission to work optimally. Mechanical upgrades are significantly more important.

Q: What is the lifespan of a 10 Speed Ford 10R140 Transmission?

A: Although there are many variables, the 10 Speed Ford 10R140 transmission lasts an average of 100,000 to 150,000 miles in unmodified trucks with average applications. Trucks with larger tires, tuning, emissions delete systems and other aggravating factors usually fail much sooner. Transmissions with religious maintenance routines that are used largely for highway miles can last longer in some cases.

Q: What is the best upgrade for a 10 Speed Ford 10R140 transmission?

A: The single most important upgrade someone can perform on a 10 Speed Ford 10R140 transmission is a valve body. The valve body is where the overwhelming majority of their problems begin, and can yield huge benefits to any application. All Ford 10R140 transmissions, regardless of application, should have one of our upgraded valve bodies.

Q: What are the service intervals of a 10 Speed Ford 10R140 transmission?

A: It is our advice that this transmission is hot-flushed and a complete fluid and filter change is executed every 25,000 miles on average. Extraordinary applications may want to perform these services more frequently, whereas highway exclusive applications can safely push a bit further between services.

Conclusion to the Ford 10R140 Transmission:

As one could see, the 10R140 transmission is lacking in mechanical and hydraulic quality. This transmission was never meant to be a "premium" option, but rather a high volume, economical option that favors EPA regulation. Fortunately, Next Gen has been adamant about bridging the gap between this naturally inferior transmission, and it's potential for tremendous success and reliability. Have questions about the 10R140 transmission? Call in and speak to one of our experts today!

Comments (16)

Hola quisiera comprar sus productos para 10R140

In 10/25/2023 bought new 2023 Superduty diesel Tremor. One month later bought F-350 Superduty diesel Tremor. At 3000 miles turbo went out on F-250. Sit in the shop 9 weeks! While in the shop I made dealer aware my F-350 transmission didn’t seem to be right. Was told they were really backed. Wait until my F-250 was repaired. After getting f-250 back decided we better drive it a little while before putting f-350 in the shop. Not to mention dealer stated they were still backed up and would be awhile before they could get it in. Drive f-250 to 4000 miles and transmission went out. Was slipping in gears and reverse was gone. Barely made it to dealer. They stated it would be a week before they could get it in the shop. After checking it they confirmed transmission was out. I informed them I didn’t want it rebuilt, didn’t want a manufactured one but a brand new one as the truck was still new with 4000 miles! Dealer agreed and they are presently arguing with Ford about it. I’m still driving F-350 and it still has a transmission issue going on but still functioning. I can’t afford to have both trucks down at once. Has anyone had an experience like this? Does anyone have any advice?

I have a 2020 F350 Super Duty with the 7.3 gas engine and the 10R140 10 speed tranny. Barely over 60,000 miles and the tranny is acting up severely. Ford dealer is saying the CDF hub needs replaced and the tranny needs rebuilt. i am NOT happy

I have a 2020 F50 with a 7.3L. Trans started acting up around 15,000 miles. It started slipping when changing gears and trying to take on in different gears..etc. Finally i could drive it any more and finally got an appointment at my Ford dealer to bring it in. It seems they are doing a lot 10R140 trans work lately. They told meat first it might be the valve body, but know they say it is the torque hub causing the issues. at least it is still under warranty this time.

I have a 2020 F-350 single wheel. I just turned over 83k is my main mode of transportation as of right now. I drive an hour plus to and from work and my 10R140 with a 6.7 diesel. Well this tra s is been acting up since about 75k (neutral/park surge, mushy shifts then hard shifts) no leaking so far. It feels like it’s going g to be a problem from now on. Have made an appointment 9/12/23 at local Ford dealership, but as always they say they have to do diagnostic test on a Trans that they know is bad. Truck is out of warranty so, they are going to find some way to blame me for the problems, and look to me paying for the new Trans, costing me what 5k-10k!!! Found a Customer satisfaction memo (that has expired according to dealer#2). That says to replace the planetary and reprogram the (tcsp?cmtp Not sure don’t have paper in front of me) so don’t know what’s going to happen Thanks Scott

Good afternoon. Can you tell me if it’s possible to replace 4R100 with 10R140? Are there controllers for controlling a 10 speed automatic gearbox, for installation on non-standard machines?

Only on start up when I put the truck in drive or reverse it acts as if it’s still in neutral and I have to rev the engine at a greater rpm that needed to move the vehicle no hard knock into gear and it only does it when I start the truck and put it in gear for the first time after starting

I have a 2020 F350 Super Duty with the 7.3 gas engine and the 10R140 10 speed tranny. Barely over 50,000 miles and the tranny is acting up severely. Ford dealer is saying the CDF hub needs replaced and the tranny needs rebuilt. Heard of any problems like this with the tranny

Is there a dipstick assembly that can be added to the 10R140?

I have a 2021 f450 pickup with 6.7 and 10 spd. It slips a bit from 8th to 9th and has always shifted insanely hard 5th gear. Your thoughts? 130000 current miles bought new 1 driver pull 30000 lbs daily.