Table of Contents:

- Introduction to the 8L90 Transmission

- In this Drivetrain 101, we will be addressing

- General Motors 8L90 Product Resources

- Popular Transmission Information Resources

- A Brief History of the 8L90 Transmission

- Problem #1 - The Torque Converter

- Problem #2 - The Input Shaft

- Problem #3 - The Valve Body

- Problem #4 - The C2 Clutch Assembly

- Problem #5 - The Oil Pan

- Problem #6 - The High Pressure Oil Pump

- Problem #7 - The Pressure Solenoids

- Conclusion to the 8L90 Transmission

Introduction to the 8L90 Transmission:

From Escalades to Corvettes, the 8L90 transmission has been employed across a cornucopia of General Motors vehicles. Unfortunately, it is not without its flaws. In fact, it’s so flawed that it was the subject of a 2018 Class Action lawsuit alleging that General Motors knew of its rancid issues and turned a blind eye, as corporate America often does. This is one of the most capable, yet mechanically imperfect transmissions used to date.

Next Gen Drivetrain is known for researching, developing and manufacturing the most advanced 8L90 transmissions, torque converters, valve bodies and parts achievable by taking advantage of all available technologies to enhance and upgrade these popular transmissions. As leading experts in the 8L90 transmission community, we are proud to bring you an installment on this unit in our popular Drivetrain 101 series.

In this Drivetrain 101, we will be addressing:

- The most popular failures we witness on the 8L90 transmission

- Ways to get the most out of your transmission

- The strengths (believe it or not, there are a few!) of this transmission

- Resources for relevant updates and upgrades

And much, much more!

General Motors 8L90 Product Resources:

- 8L90 Transmissions

- 8L90 Torque Converters

- 8L90 Rebuild Kits

- 8L90 Valve Bodies

- 8L90 Parts

Popular Transmission Information Resources:

- Top 5 Benefits of an Upgraded or Built Transmission

- Calculating Torque Multiplication Factor, Why is it So Important?

- Top 5 Ways to Extend the Life of a Factory Transmission

A Brief History of the 8L90 Transmission:

The predecessor to this failure-prone transmission was the aged 6L80 and 6L90 transmission. After a tumultuous run plagued by valve body and torque converter issues, along with further tightening emissions regulations, the 6 speed GM lineage become simply obsolete. Hence, by model year 2014, GM had began implementation of the more current 8L90 transmission. The addition of 2 more gear ratios in the 8L90 transmission expanded GM’s ability to increase engine power while maintaining a healthy CAFE (Combined Average Fuel Economy) standard.

Additionally, this transmission comes at a time when Mopar (now Stellantis) engaged in a corporate relationship with ZF allowing them to use their generally durable 8HP series transmissions. Ford, by contrast, was still trusting their semi-reliable 6R platform. This opened a void demanding GM to be more market competitive with the 8L90 transmission.

The 8L90 transmission is still in use today, but is slowly retiring in exchange for the 10L80 and 10L90 transmissions. Without further ado, we will now assess the prolific problems associated with this transmission and how to address and enhance them.

Problem #1 - The Torque Converter

As with many transmissions, the torque converter suffers from a variety of failure points. The 8L90 transmission’s torque converter, in fact, is uniquely untrustworthy. The class action lawsuit launched in December of 2018 challenges GM’s torque converter design stating that it resulted in a “vibrating” or “shuttering” behavior under certain conditions.

Granted, the problem is not this simple. There are other contributors to this problem that we will address later in this publication. Beyond the poor functionality of the design, the lockup clutch assembly affront the converter is also inadequate for literally any extracurricular application. It survives in low performance applications, but is quickly challenged as the rigor of the application increases. This results in slippage, malformation of the friction disk, scoring, heat damage and more.

Another failure more prone to truck and sports car applications is “ballooning” of the converter. Ballooning is a colloquial term used to describe excess pressure inside the converter causing it to try and expand, height wise. This can damage the high pressure oil pump or flexplate, but most frequently the oil pump.

This failure is caused by excess heat and pressure trying to push the converter pump and converter turbine away from each other and accumulating beyond the capacity of what the converter can safely handle. This is prevented in all of our 8L90 transmission torque converters by using an upgraded stator to support more efficient oil flow throughout the turbine system; a massive reliability upgrade.

Additionally, ALL Next Gen Drivetrain 8L90 transmission torque converters feature an upgraded lockup clutch assembly. Most conservatively is an upgraded clutch system using the factory geometry, ranging to a full-billet CNC machined system with 3 massive frictions and laser cut steels ensuring a nearly unusable amount of torque capacity, befitting any application and even still daily drivable; an engineering marvel.

Problem #2 - The Input Shaft

A known problem, largely in high performance and towing applications is the factory input shaft. As with most transmissions, the factory input shaft can be quite fragile when exposed to extracurricular burden, either by cause of power, high vehicle weight or a combination of the two. For example, a GMC Sierra 2500 who tows frequently with an 8L90 transmission will be similarly at risk for an input shaft failure to a C7 Corvette with large turbos.

This input shaft is additionally challenged because in order to fit 8 different forward speeds in the 8L90 transmission, you need to manufacture multiple oil circuits into the input shaft itself to feed oil to these locations. By doing so, we remove metal mass from the shaft, causing it to be weaker. This is comparable to elderly folks who lose bone density over time having easier to break bones. This is a natural complication associated with longitudinal transmissions that offer a large quantity of gears, such as 8L90 transmissions or even 10L80 and 10L90 transmissions as well.

Our solution for this is very simple. The OEM input shaft is quite functional, there are no improvements to be made in terms of modifying how it operates. The chief necessity is to make sure it simply doesn't break. Hence, we machine the 8L90 transmission input shaft out of an incredibly dense 300M material that is later heat treated to further to endorse long-term reliability. Our input shaft will capacitate extreme abuse for extended periods of time with virtually no yield, and is perfect for any demanding application.

Problem #3 - The Valve Body

The hydraulic valve system that makes it all happen, the 8L90 transmission valve body is pillaged with internal crossleaks and low quality parts galore. In this unit, the highest concentration of failure-prone components is easily the valve body assembly itself. It consists of a complex accumulation system designed to facilitate smooth shifts but rather vents unsafe amounts of oil, contributing to heat and premature failure.

Beyond that, there is a set of 7 pulse dampeners that control oil flow to oncoming clutch packs once oil flow is activated through the energization of solenoids on the side of the valve body. The problem here is that they load against the side of the valve body castings as they stroke up and down and generate bore wear over time. A simple O-Ring system or precision machining of the pistons could resolve this, but General Motors could not be bothered to do so.

At Next Gen, we only manufacture 8L90 transmissions with a set of billet pulse dampeners and recalibrated dampener springs to expedite shifts and decrease clutch drag whilst also enhancing reliability immensely. Akin to this, the singular 1-3-5-6-7 accumulator piston suffers from the same problem; side load and leakage past the piston rather than to the clutch pack. Much like the pulse dampener pistons, we replace this with a CNC machined aluminum alternative featuring a recalibrated spring to ensure the fastest, yet smoothest shifts achievable.

Lastly, there are a plurality of valves inside the valve system that are prone to longevity issues associated with poor design, such as the shuttle valve. We have systematically identified these valves, installed billet aluminum sleeves, and upgraded valves that negate the potential for future valve bore wear while also guaranteeing fast and efficient valve travel at all times. These modifications endorse fast, reliable shifts for a long time to come.

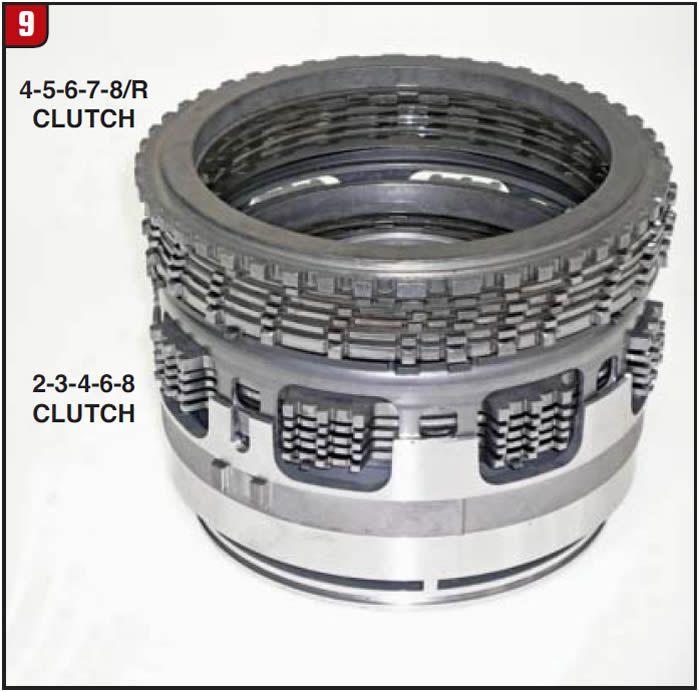

Problem #4 - The C2 Clutch Assembly

Fundamentally the overdrive clutch assembly, though also active in reverse, the C2 clutch assembly is on from 4th gear through 8th gear. As with most transmissions, the overdrive clutch system has the highest torque multiplication factor due to its long gear ratios. Because of this, overdrive clutch systems are at highest risk for slippage or failure in virtually any application. The 8L90 transmission uses "cost effective" friction materials that are more about reaching the end of the powertrain warranty than offering a long-lasting ownership experience or capacitating additional power or abuse safely.

There are many ways to address this clutch pack, and our solutions vary. For lower stress applications, we simply replace the OEM friction and steel assembly with our popular SpeedSync Laser Cut Steels and a GPZ or similar material of friction to enhance torque capacity by about 25% whilst also enhancing shift quality. For the most wanton applications, we have a re-engineered clutch system featuring multiple additional plates, further increasing torque capacity by approximately 60% over OEM, ample for the most aggressive of applications.

Unfortunately, it is a very popular practice in many transmission rebuilding services to use OEM frictions once again, or perhaps to not replace these frictions and steels at all. This unfortunately catalyzes failure for the consumer, and is not a resolution to a known failure point. At Next Gen, all built 8L90 transmissions feature some form of upgraded C2 clutch system.

Problem #5 - The Oil Pan

As an expensive 8 speed transmission, it is exceptionally important to maintain low oil temperatures to preserve the longevity of the transmission. From the factory, the OEM saves money by stamping the oil pan out of thin steel using a mold and a special tool to provide accurate shape. This is never optimal, but certainly does not endorse a healthy transmission for heavy duty applications or long term use.

In fact, the OEM oil pan is so lacking in volume that a variety of transmission pan manufactures have added in excess of a gallon to the oil volume of this transmission. Due to the obvious nature of this upgrade, it is standard on ALL Next Gen Drivetrain 8L90 transmissions to contain a cast aluminum deep pan. Expect cooler AOT (average operating temperature) with our built 8L90 transmissions.

Another lost benefit when operating with an OEM oil pan is the lack of structural support to the case. Cast aluminum deep pans function as a "girdle" that supports the case to prevent flexion, greatly decreasing the potential for a broken case. Although broken cases are not very common to this transmission, it does exist and should be noted. A cast aluminum deep pan virtually eliminates this concern.

Problem #6 - The High Pressure Oil Pump

Featuring a new design to General Motors, the 8L90 transmission uses a chain driven oil pump system where the central pump gear is driven by the speed of the motor, and the high pressure oil pump itself is in the pan area pulling oil from the pan to be distributed through the valve system. This idea is creative, but loses its ability to create oil pressure over time.

As years pile on, the unit will begin to accrue pressure at a slower rate, and also create less peak pressure over time. This contributes to a phenomenon where some customers will compromise a clutch pack, and the customer or their designated technician will replace said clutch pack, and it will immediately fail again. This happens because of hydraulic issues compromising the clutch pack rather than the clutch pack itself being inferior.

The proper resolution for all 8L90 transmission oil pump woes is to replace the oil pump in its entirety, and implement any relevant upgrades to that new oil pump. There is no safe way to properly remanufacture an old oil, used oil pump to new or better specification. We begin with a new OEM oil pump, and augment it with a steel coated pump gear to prevent future bore wear. This ensures that its day one performance is maintained throughout the lifespan of the product.

Problem #7 - The Pressure Solenoids

Adjoint to the 8L90 transmission valve body are 9 solenoids used to control activation of all friction systems inside the transmission, including the torque converter lockup clutch assembly. These solenoids are cycled tens of thousands of times throughout the lifetime of the transmission, but tend to leak oil or turn on at inappropriate times before that.

These solenoids have been updated by the OEM a plurality of times to address various different known issues within the transmission and it is imperative that one uses the latest part number for all applicable solenoids when remanufacturing and upgrading the 8L90 transmission. This will ensure both longevity and performance for the end user by guaranteeing fast and efficient shifts for many years to come.

Unfortunately, it is a common practice to either not replace these solenoids at all, or to buy cheap internationally sourced (translation Chinese) solenoids to save money. This ensures future problems and poor shift quality. All Next Gen 8L90 transmissions and valve bodies include a new set of OEM updated solenoids to guarantee these results.

Conclusion to the 8L90 Transmission:

As all can see, the 8L90 transmission is intensely complicated. Because of this, many transmission facilities simply won't touch them. Fortunately, Next Gen Drivetrain is right at home with this tumultuous transmission; specializing in sculpting them for all applications. If you still have questions about an 8L90 transmission, call in and speak to one of our friendly experts!

Comments (20)

Hello

My name is Jorge

About a year ago I bought an used 2017 Camaro SS off HGreg and after 1 month of use it presented the shudder issue, I flushed the fluid myself and it solved it for a couple months, after that I decided to buy a converter off GM parts (stock I assume) and put new fluid again, but after a couple months the issue came back, it’s been few months now and the issue still persists.Please what should I do, selling the vehicle isn’t an option I’m in love with it lol

Thanks

I have a 17 Silverado and it lost power at 75 on freeway gears won’t change into 2nd it redlined the RPM but no movement I was told my truck was in limp mode then a whining

Sounds no burnt transmission fluid should I go back to dealership with truck for recall fix

A manual transmission for trucks would be awesome 👍

Jerry, Change your fluid AND FILTER every 50K and use HIGH QUALITY Dex 6 like Valvoline and dont worry about it. Most of these trans will come out of shuddering with good fluid. I just bought a new 1500 with the 8L80e.

My 2018 is at a dealer waiting for a new transmission. When can I expect to see one.

My 2018gmc sierra had the problem of Jenkins an viberating. An they wanted me to pay for it before I contacted Gmc company

My transmission was Jenkins an shifting uncontrollably an they flushed the transmission an changed the oil in it .how long is this going to last . It should be a recall it’s gm’s problem they know about it.

I have a 2021 silverado 1500 5.3 rst 4wd crew cab z71 with the 8L90 transmission how often should i service it when im towing and how much is a transmission for this truck should i ever need one thatll last. Im stuck with this truck next 7 years and wanna make it last thanks

Is it a recall on 2016 Silverado. Mine vibrates very often

Very interesting article and well presented.