Table of Contents:

- Introduction to the Ford E40D Transmission

- Ford E40D Product Resources

- Popular Transmission Information Resources

- Do I have an E40D or a 4R100

- What are the key differences between the two?

- Problem #1 - The Torque Converter

- Problem #2 - The Valve Body

- Problem #3 - The Overdrive Clutch Pack

- Problem #4 - The High Pressure Oil Pump

- Problem #5 - The Factory Oil Pan

- Problem #6 - The Input Shaft

- Problem #7 - The Overdrive Planetary Assembly

- Problem #8 - The Solenoid Block

- Problem #9 - The Intermediate Sprag Assembly

- Conclusion to the Ford E40D Transmission

Introduction to the Ford E40D Transmission:

The Ford E40D transmissions are well known, historic transmissions that are still on the road today in many F-250 and above gas and diesel trucks from the 80's and 90's. But, did you know that many of their internal design culture originates from the C6 dinosaur transmission? It's no secret that the E40D transmissions of the world are imperfect. The main thing helping them survive throughout time is the fact that they're generally mated to lower power vehicles such as the 7.3L Power Stroke. This saves many of their failure points from view.

However, these common transmissions frequently suffer when exposed to added power, larger tires, heavier duty applications or even higher mileage. Even if nothing "breaks", these transmissions are challenged to survive past 150,000 miles before quickly degrading. This is common as OEM's only truly care about reliability inside the warranty period of the vehicle. After the 100,000 mile mark, they are no longer financially incentivized to ensure the reliability of the components of the vehicle. In this article, we will be analyzing all of the critical information, popular failure points and fixes of these historic transmissions.

Ford E40D Product Resources:

- E40D Transmissions

- E40D Torque Converters

- E40D Rebuild Kits

- E40D Valve Bodies

- E40D Parts

Popular Transmission Information Resources:

- Top 5 Benefits of an Upgraded or Built Transmission

- Calculating Torque Multiplication Factor, Why is it So Important?

- Top 5 Ways to Extend the Life of a Factory Transmission

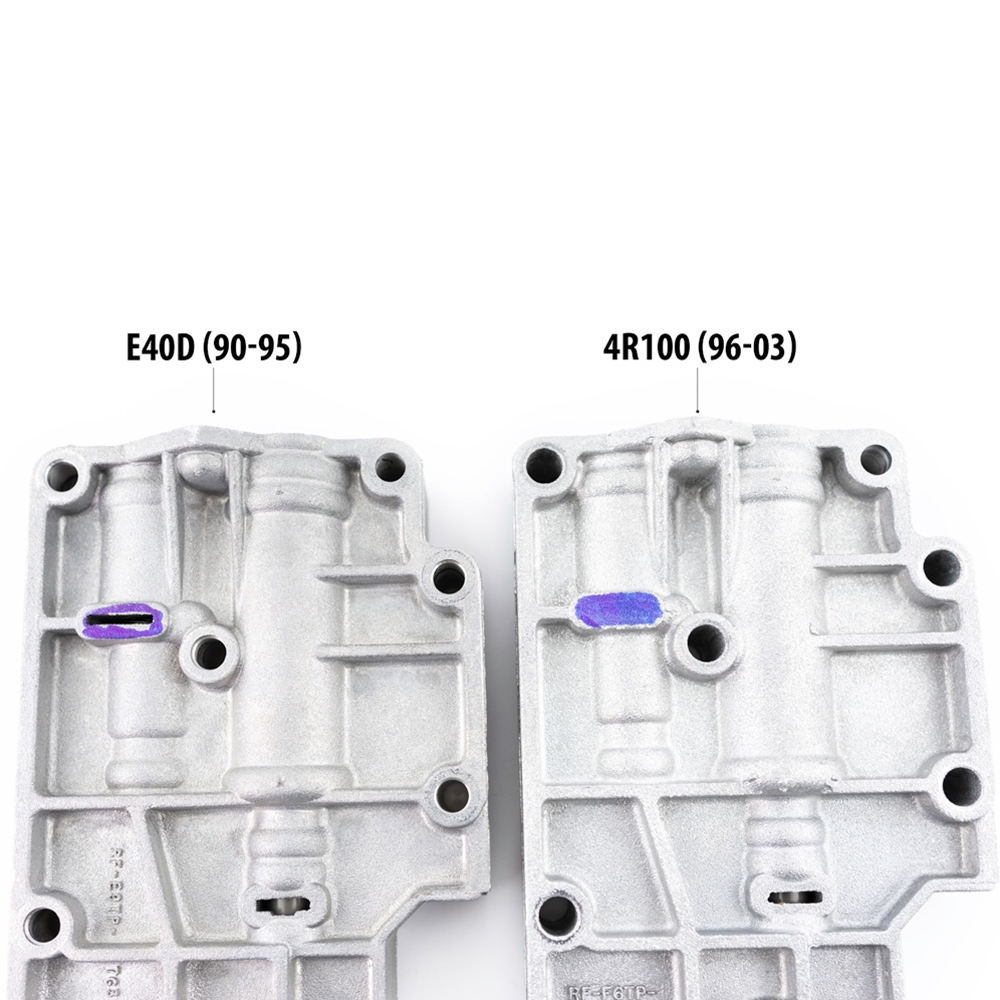

Do I have an E40D or a 4R100?

Going into the 1989 model year, Ford needed a lockup capable 4 speed transmission with overdrive to continue being market competitive. At this time, GM and Chrysler were both introducing 4 speed electronic automatics with overdrive functions. Chronologically, the E40D transmission came first. This transmission was used from model year 1989 through model year 1998.

As power levels and consumer demands grew, Ford knew they had to revisit the E40D transmission and implement some updates to make it more equipped for the new Super Duty trucks being released. In 1998, the 4R100 was released. The transmission was used early in the fleet-intensive Econoline series vehicles from 1997 as a "beta" for the product. The 4R100 transmissions production was discontinued for 2003, as the 5R110 transmission was released, ending an era of 4 speed heavy duty transmissions under the Ford brand.

As a general rule of thumb, if your vehicle is 1989 through 1998, you have an E40D transmission. If your vehicle is 1999 through 2003, you have a 4R100 transmission. There are a few exceptions to this, so if you need E40D or 4R100 transmission parts or replacements, it is best to call us to confirm what transmission your vehicle has. This will ensure fitment and reliability.

What are the key differences between the two?

Although extremely similar, the E40D transmission is not quite the same as it's newer frat, the 4R100 transmission. Firstly, the 4R100 came with the implementation of a PWM (Pulse-Width Modulated) torque converter clutch solenoid to control lockup electronically. This was designed to resolve converter drag and burnt converter clutches in high stress applications.

In addition to this, there was the implementation of an output speed sensor. This helps the transmission identify when it's slipping more accurately. The 4R100 transmission rationalizes input shaft to output shaft speed to identify slippage, similar to how a motorcycle ABS or traction control system rationalizes front wheel speed to rear wheel speed to identify slippage.

A final major difference is the oil pump. The 4R100 transmission oil pump was designed to produce line pressure faster and more efficiently than the original E40D transmission could. This was supposed to support an increase in torque capacity at the clutch packs, but only had so much impact. Now, with this fundamental understanding, we will analyze the prolific problems and solutions of the 4R100 transmissions.

Problem #1 - The Torque Converter

As with most transmissions that have a torque converter, the torque converter was designed to be cheap rather than strong. OEM's are incredibly cheap about manufacturing transmissions, especially in-house. The goal is always to maximize profits, putting the reliability of your transmission last. The Ford E40D torque converters share common failure points.

To begin, one popular failure point in these converters is the lockup clutches themselves. This is the clutch pack at the front of the converter that activates in upper gears to improve power and fuel economy. From the factory, they are extremely thin disks that have little to offer in terms of power capacity and longevity. Many heavy duty applications, tuned trucks and simply higher mileage trucks have lockup mechanisms that apply extremely slowly, or perhaps not at all. Upgraded converter clutches are a standard in all torque converters that we manufacture for the Ford E40D transmissions.

Additionally, the stator is designed so as to minimize idling emissions first, and support power and driving feel second. This is because the stator is the component used to control stall speed, the maximum allowable difference in speed between the motor and the input shaft. As with many transmissions from it's era, these torque converters were designed to allow for liberal slippage in lower gears, minimizing engine load and in turn fuel consumption at idle.

The downside is that this causes the truck to be much much less responsive, robbing you of power in exchange for intense heat in lower gears. Because of this, all Next Gen Drivetrain Ford E40D torque converters feature a precision machined stator designed to optimize for efficiency and reliability, often increasing bottom end power as well.

Problem #2 - The Valve Body

When the E40D transmission was released, one of it's major differences from it's predecessor, the C6, was the valve body. Ford had to totally redesign the valve body to allow for the usage of a 4th gear overdrive as well as a lockup mechanism. Unfortunately, they made an intensely cheap valve body assembly, prone to many crossleaks and flexion points.

In fact, the valve body is part of the reason these transmissions tend to shift so slowly and unpredictably at higher mileages. Upgrading the valve body produces immense improvements in drivability and reliability, making it an important area of analysis.

Firstly, the valve body leaks regularly at areas such as the pressure regulator boost valve, line regulator valve and 1-2 shift valve. These valves are made of cheap materials that are prone to bore wear at remarkably low mileages. This causes the transmission to be less responsive, operate at higher temperatures, and shift in an unfavorable fashion.

Additionally, the valve body is made of a soft aluminum that is prone to flexion. As it flexes, much like a head gasket, it begins to cross-pollenate different oil circuits with one another, leading to collateral issues. Although some companies are milling these valve bodies flat to support healthy seal, we have gone so far as to invent a multiple times thicker crushing style steel separator plate, creating a truly air-tight seal at the transmission.

Problem #3 - The Overdrive Clutch Pack

As with almost all overdrive transmissions, it is a challenge to keep the overdrive clutches together under heavy load. This is because overdriven gears naturally have the highest torque multiplication factor of any of the gears transmissions use; especially with the lockup clutches engaged. As a result, burnt overdrive clutches are exceedingly common on factory or cheaply built E40D transmissions.

The problem is caused by a combination of two things. One is inadequate clutch volume at the clutch pack, there is simply not enough friction material in that part of the transmission to support intense loads as many of these consumers demand. The second problem is a loss of line pressure over time due to the large quantity of crossleaks found in the oil pump as well as the valve body.

To negate this issue to our clients, we use a variety of different overdrive setups, offering upgraded clutch materials with higher braking torque and occasionally additional clutches in this portion of the transmission. This fortifies the transmission's ability to hold more torque and load under a much more expansive range of applications. As for the oil pump and valve body assembly, both are heavily modified to ensure closure of all prolific crossleaks, ensuring the longevity of the welcoming and high quality shift behavior of our upgraded transmissions.

Problem #4 - The High Pressure Oil Pump

Although the high pressure oil pump or the E40D and 4R100 transmissions are different, their issues are quite congruent. They are often reliable on day one, but quickly lose their ability to produce pressure quickly, predictably and effectively. This in turn takes from the clutch packs ability to stay together when engaged, decreasing the power capacity of the transmission.

The first concern is the pump gears themselves. As the pump gears rotate literally millions of times throughout their life, microcontaminants in the oil as well as side load will cause wear to the outer area where the pump gears ride. By doing so, it allows oil to revert out of the pump, taking directly from the clutch packs. This can be seen as a pressure drop-off on the top end of the line pressure range.

Additionally, the PWM (Pulse-Width Modulated) lockup valve inside the pump causes extremely slow clutch engagement, burning the converter clutches throughout time. We offer a standard modification in all E40D transmissions that converts this design to a simple on/off logic oil circuit, yielding faster, crisper and safer lockup clutch engagement. This valve system is also sleeved to prevent longevity concerns.

Problem #5 - The Factory Oil Pan

Although not a huge detracting factor, it should be noted that the OEM oil pan is low in volume, dismally weak in strength and contributes to sustained higher operating temperatures; an obvious negative. Aftermarket Cast Aluminum Extra Deep Oil Pans allow for added oil volume, decreasing the AOT (Average Operating Temperature) of the transmission.

Also, their rigidity supports the strength of the case by functioning as a girdle of sorts. Keep in mind, these pans cannot flex as much as an OEM pan, helping to support the case in rigorous applications where case failure can occur. This is why installing a cast aluminum deep pan can be one of the best forms of insurance against a broken case.

Problem #6 - The Input Shaft

The E40D and 4R100 input shafts are the same, and hence have the same failure points and benefits. The factory input shaft is solid, with no oil circuit traveling through the middle. This makes it generally stronger than many other shafts that are hollow internally. However, it's certainly not invincible.

Some more intense applications will suffer from input shaft failure. This can be caused by aggressive torque converter lockup, heavy loads, added power, larger tires and more. For applications as such, many prefer to use a billet input shaft, made of strengthened steel.

There are 3 different types of billet input shaft available for the E40D transmissions. The first, is 300M, a material that is about 35% stronger than the OEM shaft. Secondarily, is Maraging Steel, at roughly 60% stronger. Lastly, is AERMET, a very rare steel alloy providing nearly double the strength of the OEM transmission's input shaft. Although not everyone needs a billet input shaft, it is certainly an affordable form of insurance from expensive and demobilizing failure.

Problem #7 - The Overdrive Planetary Assembly

Tangential to the overdrive clutches failing, is the overdrive assembly itself. This planetary assembly synchronizes in speed with the input shaft and causes the output shaft to travel even faster than the input shaft. This puts a tremendous amount of stress on this specific planetary assembly.

Although it is unlikely to fail in bone-stock applications, those seeking to use their vehicles for added power or heavy duty applications will be likely to experience failure to this specific component. Fortunately, it is a standard in our middle and upper level E40D transmissions to use a billet steel overdrive planetary assembly.

In doing so, we enable the transmission to withstand a massive amount of load reliably. Further, we can use more overdrive clutches safely without the concern of applying too much stress to this failure prone component. If you desire to be rough with your transmission, a billet overdrive planetary assembly is a very cogent upgrade.

Problem #8 - The Solenoid Block

As with most electronic transmissions, solenoids are an inevitable issue as time goes on. The solenoids of the E40D transmission are confined to an assembly known as the "solenoid block", containing all of the critical electronics responsible for controlling shift behavior. This solenoid block, unfortunately, does not have a very good track record from the OEM.

As time went on, Ford progressed to redesign and update the solenoid block multiple times, giving it successor part numbers. The most current iteration of the solenoid block is quite reliable, the issue is that few people have the most current solenoid block in their transmissions. Many of the older solenoid blocks were prone to copper windings burning out internally, as well as weather-proofing concerns.

All solenoid blocks sold at Next Gen Drivetrain are only the most current iteration, preventing our clients from facing these specific concerns. It is standard in all new E40D transmissions that we offer to use a new OEM updated solenoid block.

Problem #9 - The Intermediate Sprag Assembly

Sprag assemblies are one-way clutch systems used in many transmissions to prevent things from rotating the opposite direction of what it was designed to. Like many 4 speeds, there is an intermediate sprag assembly used to do just this in the E40D transmission. Unfortunately, it's a very cheap piece of plastic that tends to blow apart in towing applications as well as tuned applications.

An easy solution is a simple drop-in upgraded sprag that features additional "elements" to more equally distribute load across the device, making it much harder to break. This is a little known modification that many transmission remanufacturing companies do not use in their E40D transmission. It's a standard practice in all transmissions and rebuild kits that we offer for these units to include a heavily upgraded 45 element sprag.

Conclusion to the Ford E40D Transmission:

As one could see, the E40D transmissions are not perfect. It's quite common that they will experience issues with hydraulics, hard parts and electronics, rendering them immobile. Next Gen has spent an enormous amount of time understanding, developing and delivering the most reliable versions of these transmissions achievable. If you still have questions about your E40D transmission, feel free to call in and speak to one of our experts!

Comments (14)

I have a 1990 E350 Centurion with the 7.3idi and the E40d transmission in it and hauling our 5th wheel when climbing hills with hazard lights on it makes the rig pulse in sync with the flashers causing it to slow down on each flash and it makes my wife and I look like we are at a headbangers concert. When I turn the flashers off it runs and pulls like normal. Would this be one of the Solon of block failures? Would replacing that block with yours fix this issue or is it just an unfixable quirk of the e40d. I found an article that said that solenoid block activates the lock in the transmission via the brake light wire is what tells it to engage the lock and give engine braking of a sort and the brake lights lighting up via that wire is how it knows and because the turn signals also make the brake lights light up so they could be on the same brake indicator on the transmission and would explain the pulsing of the truck. On my rig as with most others from this era if you had hazard lights on and hit the brakes all the turn lights on the front and brake/turn lights in the back stay lit until I take my foot off the brakes and then they flash again.

I just picked up a 1997 7.3 crew cab and to get the truck into gear you have to build rpm’s, if you stop at a stop sign or light it’s like it kicks back into neutral, we changed the pile and filter but it hasn’t changed it too much any ideas?

I have a Ford E40D automatic transmission in a ’97 Ford F250 HD plow truck w/351 engine. Reverse gear very slow going into gear. Oil smelled burnt when I pulled the pan. Any ideas on what I can do? How much for one of your transmissions for this model?

I have a 1997 f250, 4 wheel drive truck, e4od transmission, purchased in 2016. The problem it has always had is of course, with the o.d. I have had a complete flush performed, and a full synthetic fluid installed, which showed a very mild improvement in shifting firmness. I live in the mountains, and always drive with the o.d. light off, only using it on the “flats”, or long open road. I learned a trick to use when the light starts flashing, is to slow down to about 45, shut ignition off and back on, the press the o.d. button to take it out of overdrive mode, like when anticipating a slow down or stop in traffic. When I again reach highway speed, I again press the button, it shifts into o.d., and pretty much acts normal. What is a bit odd, is that I never get that flashing light on the first time using o.d. for the day, but always anytime thereafter, within 3 minutes. What is happening to cause this? I tried a diagnosis and all I heard was that it must be a slipping torque converter. However, when not in o.d. mode, I feel no slippage, but do feel it slip if I take off with the o.d. button on. Is this a common trait, sounds like the problem is limited to the o.d. mechanism itself. your input is appreciated, thanks.