Introduction:

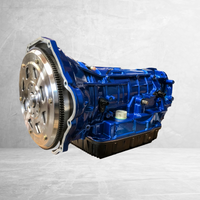

This is our recently revamped and updated Xtreme Tow® series of our 68RFE transmission lineup; designed for those who prioritize longevity and durability. The 68RFE is easily one of the most problematic and untrustworthy transmissions that currently plagues the diesel truck world. It is a promising source of overdrive failure, broken input shafts and crossleaking valve bodies to say the very least. We even did a full-length technical publication on the 68RFE, it’s problems and it’s solutions. You can read more here:

>>> Transmissions 101: 68RFE Transmission • Problems & Solutions

Fortunately, we have gone back to the drawing board in the interest of creating a product where the priorities of longevity, practicality and economy were all equal. The result was our capable and versatile Xtreme Tow® 68RFE Transmission.

Note: This is a complete transmission, not a rebuild kit. If you would like to build this transmission at home yourself, or have a transmission shop that you’d like to have build your transmission, you can use our rebuild kit version of this transmission. You can see the Xtreme Tow® 68RFE Rebuild Kit here:

>>> Xtreme Tow® 68RFE w/ Torque Converter (Rebuild Kit - 650HP)

Do You Need Fast & Easy Financing?

Next Gen Drivetrain™ proudly offers fast, easy and affordable instant financing. You can finance your order straight from your computer or phone in as little as 5 minutes through companies like Affirm, Katapult & Shop Pay Installments. Some options offer as low as 0% APR! To learn how, check out our EZ Financing guide below:

> Next Gen Drivetrain™ Fast & Easy Financing Guide

Chrysler 68RFE Transmission Product Resources:

- 68RFE Transmissions

- 68RFE Torque Converters

- 68RFE Rebuild Kits

- 68RFE Valve Bodies

- 68RFE Parts

Popular Transmission Information Resources:

- Top 5 Benefits of an Upgraded or Built Transmission

- Calculating Torque Multiplication Factor, Why is it So Important?

- Top 5 Ways to Extend the Life of a Factory Transmission

Why Choose an Xtreme Tow® Series Transmission?

Xtreme Tow® Series transmissions are a unique series of transmissions developed by Next Gen Drivetrain™, specifically for our truck and SUV customers seeking the ultimate work-horse. These transmissions generally feature upgraded pumps, valve bodies, torque converters, drums and friction materials whilst also consisting of a complete and total remanufacturing in excess of all OEM specifications.

Xtreme Tow® Series transmissions shift crisp but modestly, operate at comfortably low temperatures and are designed to optimize for longevity, low cost of lifetime maintenance and direct OEM compatibility while also capacitating the added power of potential modifications that are common in the working-vehicle community.

You can find Xtreme Tow® Series transmissions in everything from tow-trucks, to over-achieving daily drivers to modestly upgraded family trucks. Its low cost of maintenance and tremendous durability make them an attractive option for the majority of people looking for a mid level transmission with top shelf reliability.

If that isn’t attractive enough, these transmissions feature a 2 year, unlimited mile warranty. If you’re looking for a maxed-out reliability build, short of unnecessary racing parts that are not relevant to your application, the Xtreme Tow® Series transmission is the pristine option for you.

Why Choose Next Gen Drivetrain, Inc.?

Next Gen Drivetrain, Inc. is a Veteran Owned and Operated company in gorgeous San Diego, California that specializes in engineering, developing and manufacturing the height of automotive transmission technology. Unlike most transmission companies that simply buy often foreign-made parts from their supplier, rebuild a transmission and sell it to you at an upcharge, Next Gen Drivetrain, Inc. is not a transmission shop or simple transmission rebuilding facility. We are an engineering and manufacturing firm specializing in automotive transmission technology, ranging from exotic imports to muscle cars to diesel trucks.

We’ve invented dozens and dozens of different unique transmission parts from nothing that are exclusive to Next Gen Drivetrain™, not to mention developing over 100 different custom transmission and torque converter build sheets. We do not sell our popular inventions such as our Project Carbon® valve body upgrade kits to other large transmission companies, making Next Gen Drivetrain™ products truly unique to Next Gen Drivetrain™. Next Gen Drivetrain™ parts are proprietarily engineered in-house and manufactured right here in San Diego, California.

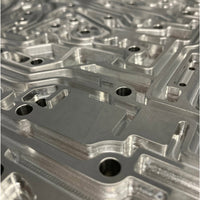

Further, everything we develop is designed to be the highest quality and best functioning component first, with all other metrics secondary. For example, things made of Aluminum will often be Steel or Tungsten at Next Gen Drivetrain™. Things that are cast at other companies will often be CNC Machined at Next Gen Drivetrain™, and so on. When purchasing a Next Gen Drivetrain™, you can be assured that you’ve chosen the most premium option available, far more than some basic updates and a colorful painted exterior.

We highly encourage you to compare our build sheets to any similarly priced product by a so-called “competitors” as you will see Next Gen Drivetrain™ products have no true equivalent, featuring the most extensive set of deliverables at their respective costs. Best of all, we are always just a phone call away, and happy to discuss your personal needs at length to ensure you’ll love your new product. Procuring your transmission through Next Gen Drivetrain™ is truly boutique experience. Call in and speak to an expert today!

Xtreme Tow® Products are Best For:

- Stock to Moderate Power Increases

- Daily Driving

- Slightly Firmer Than Stock Shifts

- Faster Shifting

- Extreme Towing/Hauling

- Commercial/Industrial Use

- Ultra-High Longevity

- Low Cost of Lifetime Maintenance

- Low Operating Temperatures

- Off-Road Use

Our 10-Step Transmission Remanufacturing Process:

- The first step in our remanufacturing process is a complete and total disassembly and inspection of all internal components, including the torque converter, geartrain, hydraulics, clutches and/or electronics.

- All wear components, such as bushings, bearings, washers, gaskets, seals, O-Rings, clutches, steels and more, are thrown away regardless of their health or usability, even if brand new.

- An intense cleaning session using the highest quality cleaning agents available to modern manufacturing ensues, steam tanking and hand cleaning these parts for up to 8 hours.

- We begin our inspection of the few remaining core hard parts to ensure that they are 100% re-usable, unworn and undamaged. Should a core part (such as a case) be irreparably deficient or unusable, it is properly discarded and replaced with a brand new one.

- At this point, the assembly process begins. All components consistent with your build sheet are staged and the proper machining, assembly and calibration of the product begins.

- Upon completion of all assembly, applicable components are individually tested on their respective machinery to ensure proper function and integrity, specifically hydraulics and electronics.

- At this point, final assembly begins. All pre-assembled internal components are then completed within the case, tested and forwarded to quality assurance.

- Prior to leaving our facility, a separate team member then inspects the final product, ensuring that the product matched the build sheet, and finishing touches like sensors or pan bolts are retorqued to assure future success for our product.

- At this point, the completed transmission is crated, the logistics of delivering your product are coordinated, and the item will proceed to shipping to prepare for embark to it’s new home.

- Upon completion of the 9 previous steps, you will receive notification of the product’s completion, passage of our quality control measures, and tracking information once applicable!

Xtreme Tow® 68RFE Transmission Build Specifications:

- Billet Lockup Apply Piston

- Custom Clutch and Steel Stack-Ups w/ Added Clutches

- Billet OD/Reverse Plate

- Billet Turbine Hub

- Billet CNC Machined Stator

- Billet Torque Converter Cover

- Billet Multi-Disk Lockup Mechanism

- Steel SFI Approved Flexplate

- Cryogenically Hardened OD Hub Assembly

- Custom 2nd Clutch Apply Piston

- Molded Apply Piston Kit

- Custom Double-Sided Converter Clutch

- Billet Accumulator Piston Set

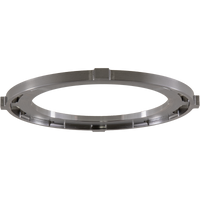

- Billet Project Carbon® Channel Plate

- Recalibrated Accumulator Spring Set

- Self Cleaning Low/Reverse Switch Valve

- Steel CNC Ground Solenoid Switch Valve

- Billet Project Carbon® L/R Sprag

- Precision Machined SSV Bore

- Precision Flattened Valve Body Mating Surfaces

- Precision Flattened Oil Pump Mating Surfaces

- Steel Laser-Cut Separator Plate w/ Custom Oil Circuitry

- Steel Accumulator Girdle

- Extra Thick OD Snapring Update

- Central Pump Gear Bushing

- Billet Torque Converter Limit Valve Sleeve

- Polished Pump Separator Plate

- Recalibrated Pump Accumulator Piston Springs

- Next Gen Drivetrain™ Proprietary Drainback Circuit Modification

- FIFTEEN clutches in OD - a 25% increase!

- 33% Added Friction Area in 2C

- 33% Added Friction Area in 4C

- High Energy Low/Reverse Clutches

- High Energy Reverse Clutches

- High Energy Underdrive Clutches

- Extra Deep Transmission Pan

- Bronze Bushings

- OEM Torrington Roller Bearing Kit

- (2) OEM Speed Sensors

- OEM Pressure Transducer

- OEM Solenoid Pack

- OEM Paper/Rubber Gasket & Seal Kit

- OEM Sump Filter

- Billet Spin-On Filter Adapter

- OEM Spin-On Filter

Conclusion:

Do not be fooled by counterfeit quality Chrysler 68RFE transmissions. Regardless of your application, Next Gen Drivetrain™ is committed to engineering and manufacturing the most reliable, high quality transmissions achievable for these complex and unique units. Still have questions? Call in and speak to an expert today!

Note: Some product photography may display optional add-ons such as custom powdercoating, adapters for specific vehicles or similar. For a precise list of parts and services included in this product, please consult the build specification sheet listed above. If you have absolutely any questions, please feel free to contact us directly. It is our privilege to serve you.